Methanol

100 +

licences

60 million

tonnes/yr licensed methanol production

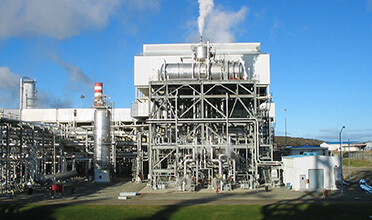

The potential of methanol

Methanol is an important and highly versatile chemical used to produce hundreds of every-day products. From plywood, paint, and adhesives to clothing and pharmaceuticals, it improves our quality of life. It is also a cleaner-burning and safe alternative to conventional fuels and a potential enabler for decarbonisation.

Today, methanol is mainly produced from synthesis gas obtained from fossil fuels, but it can also be obtained from sustainable sources. As the production of renewable methanol continues to scale up, it will provide a long term, carbon-neutral energy solution to different transport sectors.

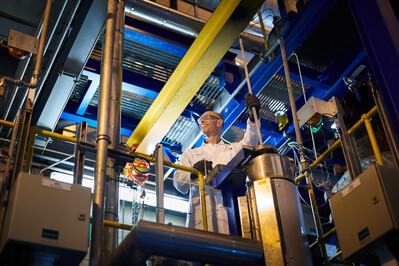

Unlock the possibilities with us

As the world’s leading methanol synthesis technology and catalyst supplier, we are passionate about methanol, and are proud to offer the most efficient and reliable solutions in the market. Our goal is to drive profitability quickly and easily for our clients. All our offerings are fully supported by our technical services team, who are here to ensure processes run smoothly and our customers are cared for on their methanol journey.

We are committed to reducing the impact of our technology on the planet. Our cutting-edge methanol solutions deliver the highest yields using the most sustainable process designs to date. Learn more about our Life Cycle Assessment (LCA) study, where we measure and compare the environmental impact of JM methanol production flowsheets, which are licenced to customers for methanol production.

Our methanol process technologies:

-

A fuelless reforming process which delivers minimal direct CO₂ emissions without carbon capture and is ready for electrification. It combines our unique gas heater reformer with an autothermal reformer (GHR+ATR).

LEARN MORE

-

An elegant process, with world-class performance and reliability, which uses our “long-neck” autothermal reformer (ATR) and our superior quality methanol synthesis catalyst.

LEARN MORE

-

A robust process which combines steam methane and autothermal reforming (SMR+ ATR) to deliver consistently high performance for a wide range of natural gas compositions.

LEARN MORE

-

A well-established, oxygen-free process which is based on steam methane reforming (SMR) and can deliver large methanol capacities.

LEARN MORE

-

A single process to make methanol and ammonia combining Johnson Matthey and KBR’s market leading technology, achieving maximised efficiency and savings while delivering operational flexibility and world-class reliability.

LEARN MORE

-

Production of low carbon intensity methanol, from waste CO₂ streams of biogenic origin and green H₂ generated by water electrolysis.

LEARN MORE

-

Production of renewable methanol using synthesis gas obtained from the gasification of biomass or organic municipal waste.

LEARN MORE

-

Production of more sustainable methanol using synthesis gas obtained from the chemical conversion non-recyclable municipal and industrial waste.

LEARN MORE

-

Transformation of industrial off-gases containing CO, CO₂ and H₂ into valuable methanol.

LEARN MORE

-

A suite of ready-now technologies to significantly reduce carbon emissions of new and existing assets.

LEARN MORE

-

An advanced digital platform allowing customers to efficiently monitor, adapt and optimise processes as conditions change.

LEARN MORE

High performance methanol catalysts and absorbents

Johnson Matthey’s methanol processes combine our most efficient technology with cutting edge catalysts and absorbents to maximise plant performance and reduce operating costs.