Biodiesel-process

Biodiesel process

Biodiesel, being derived from plant-based natural oils, offers great environmental benefits as a renewable alternative to conventional diesel made from fossil fuels.

However, a potential drawback of this product is its requirement for high-quality virgin oil feedstocks, which are available only from vegetation used as food. Consequently, the environmental demand for renewables competes with the imperative to feed the world’s growing population and causes high-quality virgin oil prices to increase.

Johnson Matthey’s DAVY™ biodiesel process offers a solution to this problem. Our flowsheet can employ inexpensive low-quality non-edible feeds, in addition to virgin and higher-quality oils.

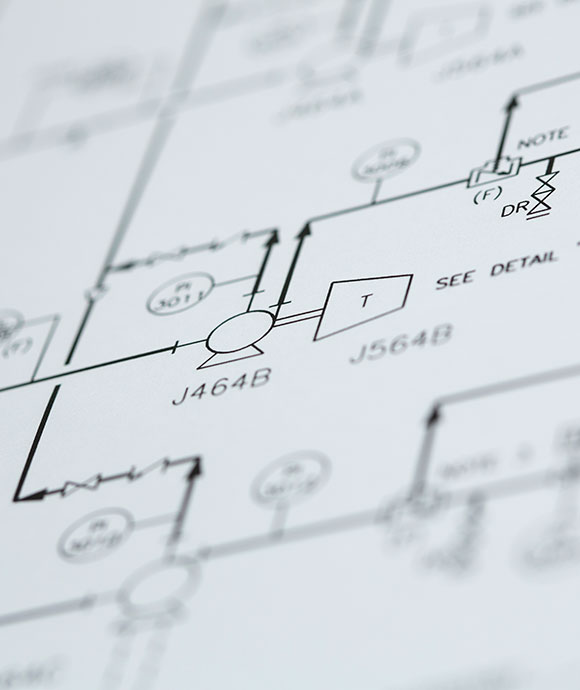

The DAVY biodiesel process flowsheet is evolved from our natural detergent alcohol (NDA) and butanediol (BDO) processes. Our biodiesel process converts fatty acids from upstream hydrolysis to biodiesel-grade fatty acid methyl esters (FAME). This process also yields a high-value clean glycerol coproduct.

Feed stock oil is split by traditional oil hydrolysis to produce a clean water/glycerol stream and fatty acid. The fatty acids are reacted with methanol in our advanced process to give methyl esters. The esterification process is extremely efficient and simple to operate and the resulting esters can be fed directly to the methanol removal section. Methanol is removed from the crude product to give market quality biodiesel, whilst recovered methanol is recycled for re-use.

In summary, the DAVY biodiesel production route offers extensive environmental and economic benefits by converting a high-acid-content, low-value feed into a high value renewable fuel. These benefits include:

- feedstock flexibility

- simplified catalysis, process efficiency

- high value glycerol by-product

- reaction selectivity.