Battery

systems

World-class, tailored solutions

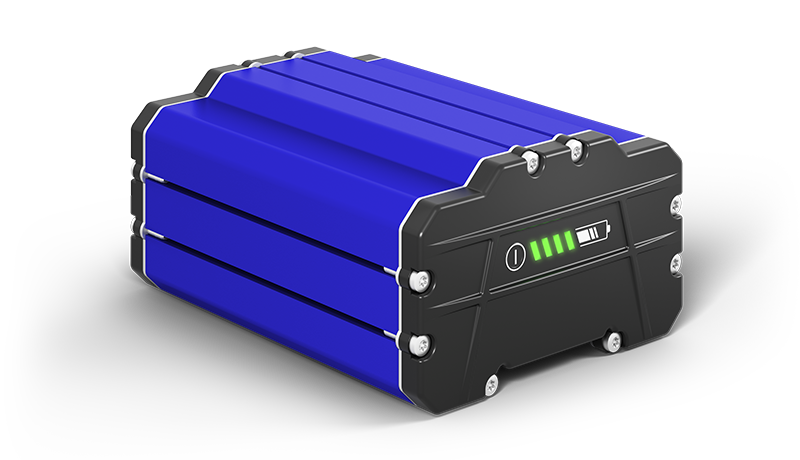

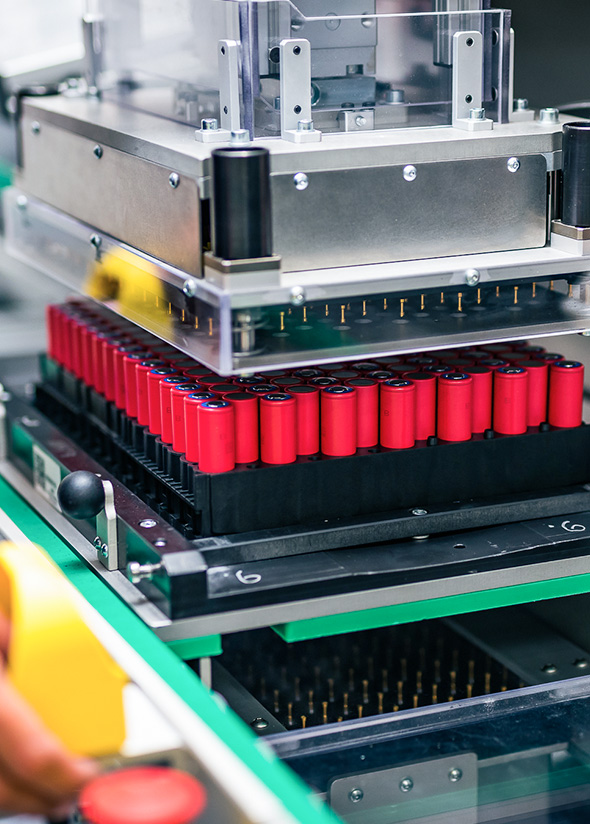

Advanced battery systems designed, engineered, and manufactured for cordless applications with varying power and capacity requirements.

Learn more

20+ years of experience

delivering to top global brands

The modern battery market is facing significant challenges. The increase in automation and the development of battery-powered applications now forces manufacturers to look for new solutions that go hand in hand with technological progress and trends. The demand for innovative, durable, and reliable battery systems continues to grow, and consumers today expect applications that run longer without sacrificing energy efficiency.

As a leading European manufacturer of advanced battery systems, we have been working with our customers for over 20 years to make their products stand out in highly competitive markets.

About usVolume and tailored partner solutions

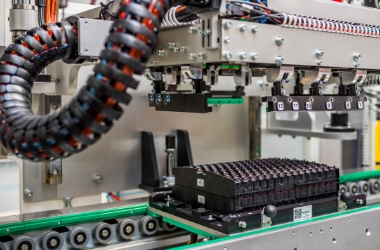

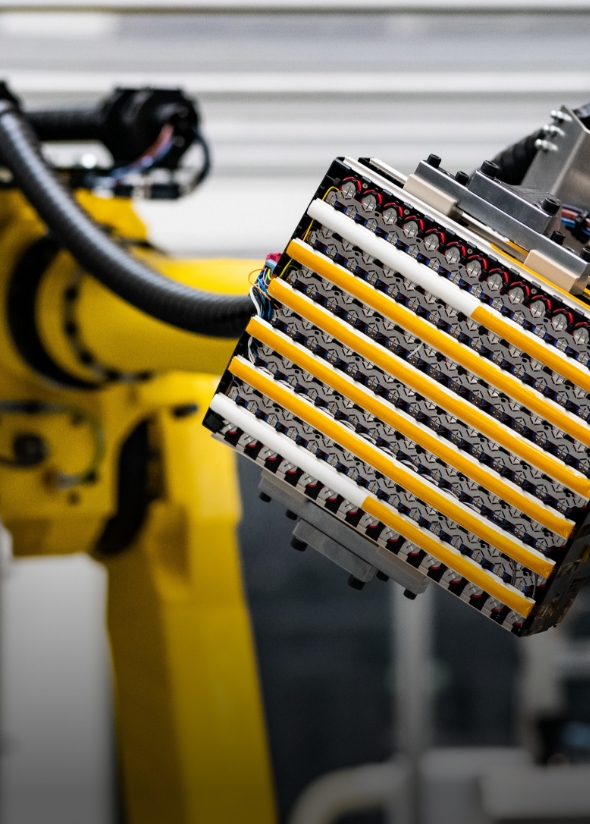

The best technology on the market at your fingertips. Assembling several million battery packs a year, our dedicated process designers and engineers have the skills and experience necessary to manufacture advanced battery systems safely and reliably while remaining cost-efficient.

Work with us for professional support with design to final delivery, plus take advantage of our range of manufacturing options that will ensure you quickly scale to meet the requirements of evolving markets.

OUR TECHNOLOGYSupport in all key areas

-

01

Optimise your battery packs with more efficient assembly processes at scale

-

04

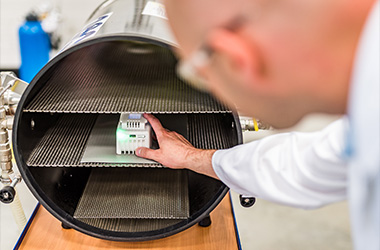

Create in-house prototypes at each stage of the project

-

02

Design a complete battery system, ensuring high performance and quality

-

05

Perform complex laboratory testing for maximum performance

-

03

Source high-quality, affordable components for battery cells

-

06

Deliver cost-effective production lines and assembly processes

Lithium-ion battery manufacturer

Lithium-ion batteries have become a vital component in various applications, from small electronics such as smartphones and laptops to large-scale energy storage systems and electric vehicles. At Johnson Matthey Battery Systems, we understand the importance of providing reliable and high-quality battery cells that meet the diverse needs of our customers.

Our commitment to innovation and sustainability has made us a trusted supplier to customers across Europe and beyond. Our state-of-the-art facilities, cutting-edge technology, and strict quality control measures ensure that our lithium-ion battery cells meet the highest standards for safety, performance, and efficiency.

We are passionate about our work and take pride in developing and manufacturing innovative battery solutions that provide long-lasting, reliable, and sustainable power for various applications. Our team of experts works closely with our customers to understand their unique requirements and design custom solutions that meet their specific needs. So if you are looking for a lithium battery manufacturer in Europe, then look no further than us.

Battery cells

Being a lithium battery producer, core product offering is our range of lithium-ion batteries, which are manufactured in our state-of-the-art facilities using cutting-edge technology and strict quality control measures. We produce cells in a variety of sizes and configurations to meet the diverse needs of our customers, and our team of experts is always available to help design custom solutions for specific applications. If you are searching for a lithium battery producer, then we are here to help.

We offer more than just high-quality battery

Being a European lithium battery manufacturer, we understand that our customers require more than just high-quality batteries. That’s why we offer support in all key areas, including design, testing, and certification. Our team of engineers is available to help customers optimize their battery systems, from choosing the right cells to designing the most efficient packaging and cooling systems. We also provide testing services to ensure that our cells meet the highest standards for safety and performance, and we can assist with certification and compliance requirements for different markets.

Get volume and tailored partner solutions

We understand that different customers have different needs when it comes to battery cells, which is why we offer both volume and tailored partner solutions. For larger customers who require high volumes of cells, we can provide efficient, cost-effective manufacturing processes and logistics support. For smaller customers or those with unique requirements, we offer tailored partner solutions that allow us to work closely together to design the perfect battery for their needs.

We design advanced battery systems

Our advanced battery systems are designed to provide optimal performance, safety, and efficiency for a range of applications. From electric vehicles to grid-scale energy storage, we work closely with our customers to understand their needs and design custom solutions that meet their requirements. Our battery systems are built to last, with a focus on sustainability and long-term reliability.

20+ years of experience

With over 20 years of experience in the industry, Johnson Matthey Battery Systems is a trusted partner for customers seeking high-quality lithium-ion batteries and advanced battery systems. We are committed to innovation and sustainability, and we invest heavily in research and development to ensure that our products are always at the forefront of the industry.

Whether you are looking for a high-volume battery or a tailored partner solution, we have the expertise, experience, and commitment to provide the battery solutions you need. Contact us today to learn more about our lithium-ion battery cells and how we can help power your applications.

What are lithium-ion batteries?

Lithium-ion batteries, or Li-ion batteries, are a type of rechargeable battery that uses lithium ions to store and release energy. These batteries are commonly used in consumer electronics, such as smartphones, laptops, and tablets, as well as in electric vehicles and renewable energy storage systems. These batteries have many advantages over traditional lead-acid batteries, such as higher energy density, longer lifespan, and lower self-discharge rates.

Lithium-ion batteries are an important technology that has revolutionized many industries, from electric vehicles to consumer electronics. The 24V, 36V, and 48V lithium-ion batteries, high-capacity lithium batteries, and high-power lithium batteries are all types of lithium-ion batteries that are commonly used in different applications. With their high energy density, long lifespan, and other advantages over traditional batteries, lithium-ion batteries are sure to continue to play a key role in the transition to a more sustainable and efficient future.

At Johnson Matthey Battery Systems, we offer a range of high-quality lithium-ion batteries for various applications. Our batteries are designed to deliver reliable and consistent performance, and they are manufactured using the latest technology and materials.

We offer a variety of lithium-ion batteries, including the 24V lithium battery, 36V lithium battery, and 48V lithium battery. Our high-capacity lithium batteries are perfect for applications that require a lot of energy storage, while our high-power lithium batteries are ideal for applications that require a lot of power.

24V Lithium Battery

The 24V lithium battery is a high-capacity lithium-ion battery that is commonly used in electric vehicles, solar energy storage systems, and other applications where high energy density and long cycle life are required. The 24V lithium battery is a type of lithium iron phosphate (LiFePO4) battery, which has many advantages over other types of lithium-ion batteries, such as higher thermal stability, improved safety, and a longer lifespan.

36V and 48V Lithium Battery

36V lithium battery and 48V lithium battery are also popular in many applications, particularly in electric bicycles and other small electric vehicles. These batteries offer a good balance between energy density and power output, making them ideal for applications that require both high energy and power, such as electric bicycles and scooters.

High Capacity Lithium Batteries

High capacity lithium batteries are ideal for applications that require a lot of energy storage, such as solar energy storage systems, electric vehicles, and backup power systems. These batteries have a high energy density, which means that they can store more energy in a smaller space than other types of batteries, such as lead-acid batteries.

High Power Lithium Batteries

High power lithium batteries are designed to deliver high levels of power quickly, making them ideal for applications that require a lot of power, such as electric vehicles, power tools, and robotics. These batteries have a high power density, which means that they can deliver more power per unit of weight than other types of batteries.

At Johnson Matthey Battery Systems, we are committed to providing our customers with the highest quality lithium-ion batteries and the best customer service. Contact us today to learn more about our products and services, and to find out how we can help you with your battery needs.