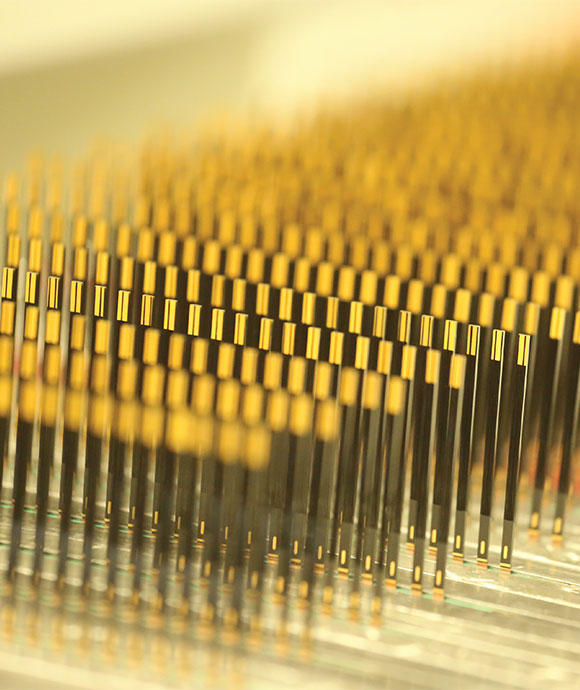

Piezo-products

Piezo and next generation technology development

Our scientists’ expertise coupled with our commitment to R&D enables us to develop innovative technologies that solve real world challenges on a global scale.

We combine our material science expertise with cutting-edge technologies to provide the best solutions to our customers. We are the market leaders in Piezo benders that offer excellent flow control and microdosing in drug delivery systems. Our Piezo actuators, sensors, and atomizers have wide applications in:

- drug delivery

- robotics

- prosthetics

- BCI

- ultrasound technologies.

The braille keyboards that use our actuators improve the quality of life for millions of visually impaired people. The next generation medical devices have implantable pulse generators that can greatly benefit from our Piezo energy-harvesting technologies.