Gas-to-liquids-process

Gas to liquids process

Converting natural gas to liquid fuels is an attractive prospect, particularly where the gas resource is effectively stranded in a remote location, making the conventional routes to market, by long distance pipeline or conversion to liquefied natural gas (LNG) for shipment by sea, uneconomic. The Fischer Tropsch process for converting methane containing gas to waxy paraffins and liquid fuel was discovered in the 1920s. However, it is only much more recently that political, oil and gas market and environmental issues have brought this process to the attention of the international petroleum industry.

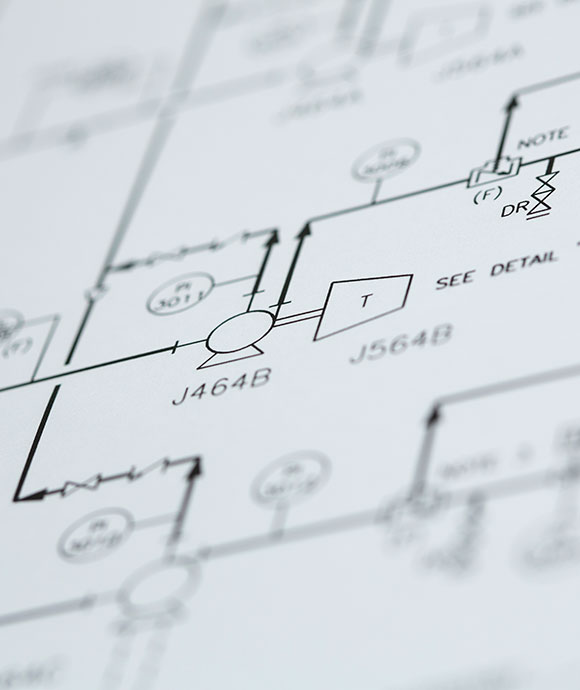

The gas to liquids (GTL) process comprises three main process steps, firstly the reforming of natural gas to synthesis gas, a mixture of gases containing hydrogen, carbon monoxide, carbon dioxide and unreacted methane, secondly the Fischer Tropsch (FT) conversion of carbon monoxide and hydrogen to long chain hydrocarbons and thirdly the upgrading and refining of these hydrocarbons into a specific state of liquid fuels.

Johnson Matthey's DAVY™ technologies together with BP has GTL technology available for project development. The company has long been a supplier of technology for the production of synthesis gas with our expertise forming the basis of over 300 projects worldwide.

Today we offer technologies for the production of synthesis gas based on steam methane reforming, compact reforming, auto thermal reforming, combined reforming and gas heating reforming.

Johnson Matthey, in collaboration, with BP is able to offer fixed bed cobalt based catalytic synthesis. The resulting wax can then be hydrotreated to produce naphtha, diesel and other fuel products.

Contact us for further information on our DAVY and BP GTL process.