Monoethylene-glycol-MEG-process

Monoethylene glycol (MEG) process

Johnson Matthey now offer a new DAVY™ MEG licensed process in partnership with Eastman.

MEG is the most common industrial diol which is used in manufacture of polyester fibre, fabrics and polyethylene terephthalate (PET) resin used for production of plastic bottles. Other industrial uses are as a coolant, heat transfer agent, antifreeze and a hydrate inhibitor in gas pipelines. Current worldwide consumption of MEG is approximately 30 million tonnes per year and has grown by over 5% each year during the last decade.

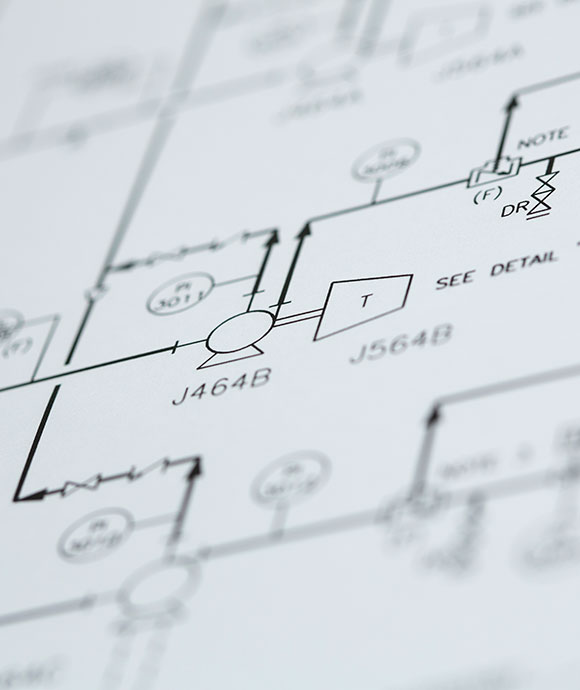

Our new process using proprietary catalyst developed by Johnson Matthey and Eastman enables the production of MEG from methanol via formaldehyde. This offers a unique and exciting opportunity for methanol and/or formaldehyde producers who are interested in diversifying their product slate.

The key feedstocks are formaldehyde, carbon monoxide and hydrogen and besides MEG, the process produces a small amount of valuable diethylene glycol (DEG).

This new technology has been developed in our Global Research & Development Centre and demonstrated in mini-plants which are designed, constructed and operated by highly skilled and experienced professionals.

Comprehensive data collection from long-term operation of the mini-plants has enabled us to develop the design for commercial scale plants with MEG production capacity ranging from 200,000 to 500,000 tonnes/year.