CATACEL SSR catalyst for steam reforming

Johnson Matthey’s CATACEL SSRTM catalyst technology is a proven high-performance, direct replacement catalytic solution for enhancing hydrogen production from natural gas through existing steam methane reformers (SMRs). CATACEL is the technology of catalyst coating thin metal foil substrates. SSR – Stackable Structured Reactor is the industrial scale steam methane reforming product that uses CATACEL technology to remove traditional pelleted reforming catalyst barriers in SMR operation.

This technology enables increased throughput and reduced energy consumption and related emissions, with a reduced pressure drop that enables increased production with fewer mechanical constraints and limits than with traditional pelleted catalysts.

Replacing traditional SMR pellet catalyst

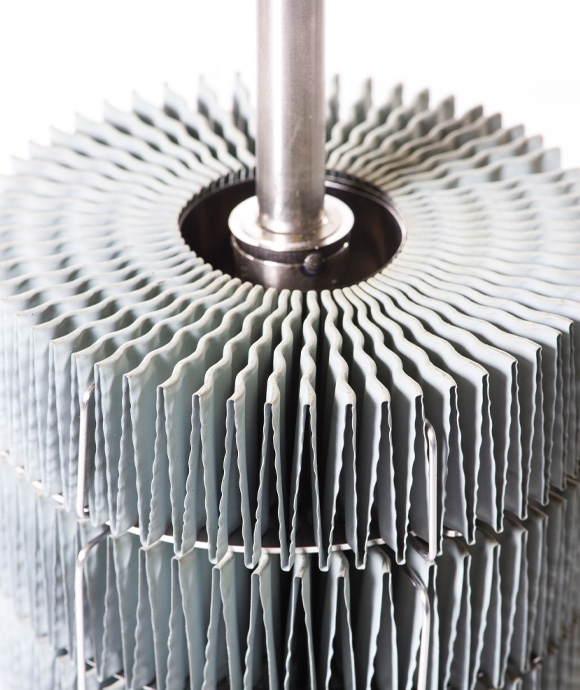

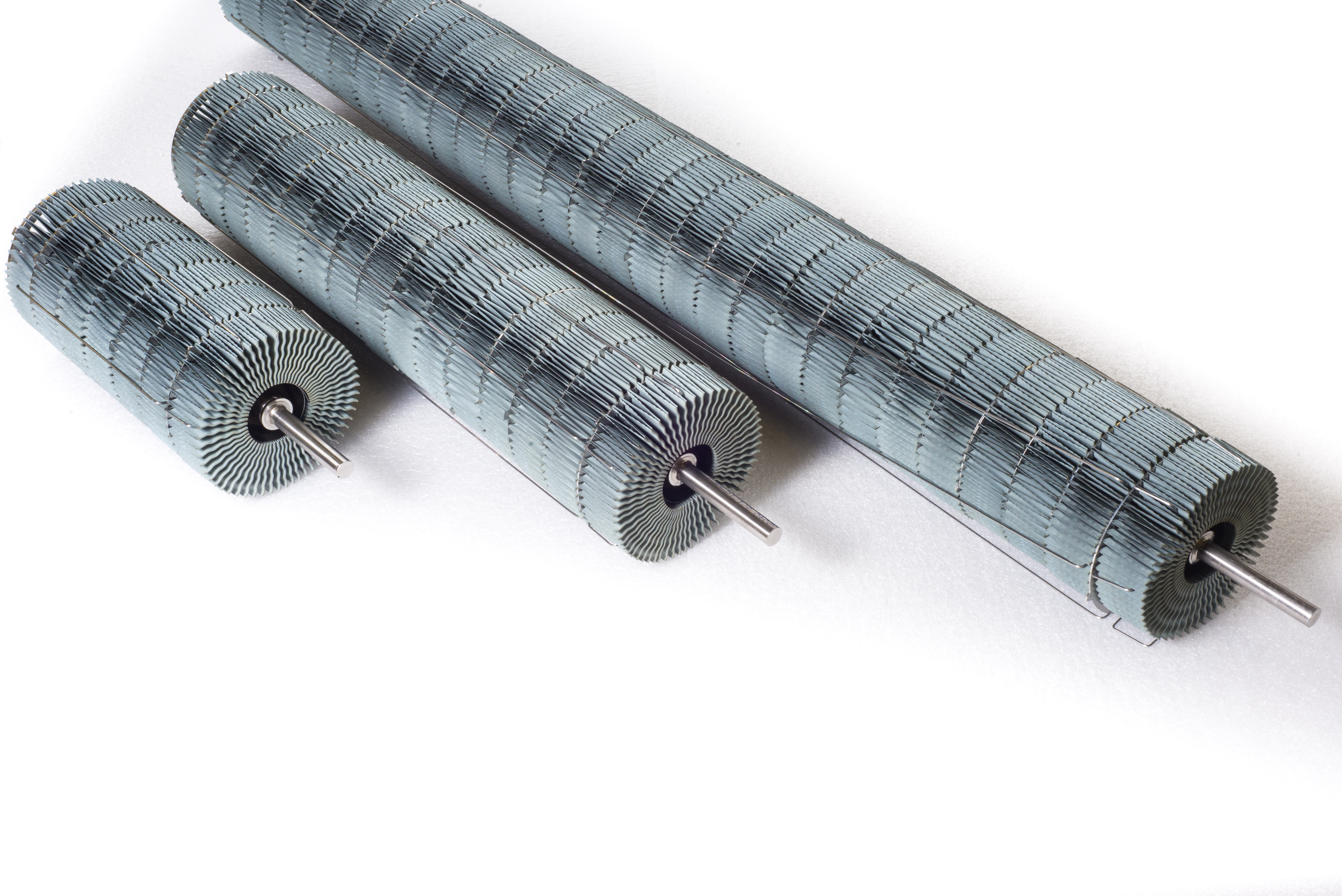

CATACEL SSR technology is a breakthrough catalyst system that significantly enhances plant performance by replacing the traditional SMR pelleted catalyst with an innovative assembly of metal foil fans coated with reforming catalyst. These precisely engineered assemblies are stacked to fill the entire catalysed length of each reformer tube.

The process gas flow through the stacked assemblies creates a targeted approach to gas contact with a significantly larger active catalyst surface per unit volume while improving heat utilization from the inside reformer tube wall to fuel and intensify the steam methane reforming reaction. SSR catalyst-coated fans continuously impinge the process gas flow against the inside tube wall, breaking down any stagnant gas layer that insulates and limits heat transfer from the tube wall to the catalyst increasing heat utilization from the fired reformer into the tube side process gas.

This SSR design allows the fans to guide the gas flow from one stack layer to the next, assuring contact with the catalyst-coated surfaces. The total reactive surface area provided by these fans exceeds that of the pellets they replace, resulting in significantly improved catalytic activity. Attempts to achieve this level of performance with traditional pelleted reforming catalysts results in a high pressure drop that would require more costly mechanical debottlenecks of the SMR to achieve the same level of performance.

Improve the efficiency of the SMR process

The improvements in heat transfer, activity, and reduced pressure drop enable significant increases in production rates; 15-20% has been observed. The high void space created within the reformer tube and stability of the CATACEL SSR structure means a low pressure drop value is achieved with no increase in pressure drop over time. Pelleted reforming catalyst crack and break from the loads created with expansion and contraction of the reforming tube. The CATACEL SSR’s foil stacks expand and contract with the reformer tubes, delivering high performance over a long service life.

Even without increasing the hydrogen production of the existing plant, the significant improvement in the heat utilization with SSR within the reformer tubes results in much improved use of the firing of the furnace side of the reformer. This results in lower tube wall temperatures (TWTs), fuel usage, and related emissions reducing reformer tube stress and potential production curtailment limits. The lower pressure drop and improved activity achieved with CATACEL SSR reduces flowsheet stress allowing improved operation below mechanical limitations that may exist within the flowsheet.

Overall, the operating benefits of using JM’s CATACEL SSR technology to improve the efficiency of the SMR process have been well-documented and proven in commercial units worldwide. These benefits include:

- Increased hydrogen production

- Substantial fuel savings

- Reduced and managed CO2 and firing related emissions

- Reduced tube stress with lower tube wall temperatures

- Removal of pressure drop limitations.

- Improved flowsheet stresses with increased production load

Steam methane reforming integration

CATACEL SSR can be installed in the existing tubes of the steam methane reformer within a normal changeout schedule. CATACEL SSR has experienced over 500,000 hrs of operation in all kinds of steam reforming geometries providing charge to charge consistency in performance with minimal degradation over the typical turnaround lifecycle.

When installed as a direct replacement for pelleted catalysts, CATACEL SSR can generate significant economic returns, often in as little as 9-12 months. To try to achieve some of the benefits of CATACEL SSR with pellets, a high pressure drop characteristic is usually needed which results in higher capital cost mechanical debottlenecks to take advantage of the higher performing pelleted catalyst.

CATACEL SSR accomplishes even greater improvements at a low pressure drop, making It the best choice for a low capital technology to meet the growing hydrogen demand now and in the years to come.

Watch our webinar on optimising hydrogen production with advanced catalyst solutions

Enter your email to continue