Methanol synthesis catalysts will typically undergo a degree of shrinkage (and settling) following reduction and subsequent start-up.

Minimise the impact of pellet diffusion in methanol synthesis

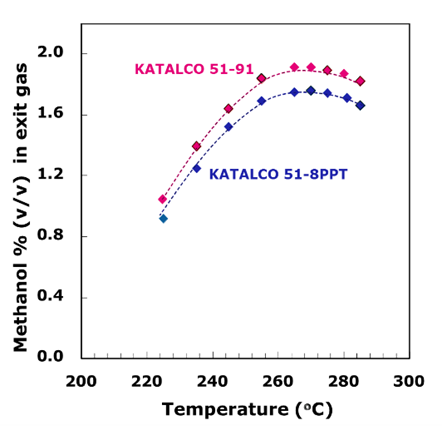

KATALCOTM 51-91 has been designed to minimise the impact of pellet diffusion limitations allowing for high pellet effectiveness to maximise methanol production.

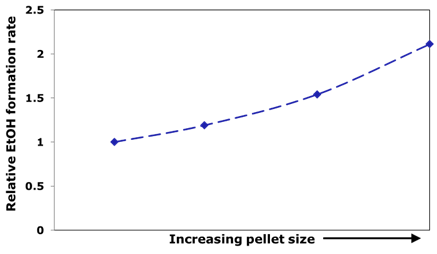

KATALCO 51-91 is a smaller pre-shrunk variant of the well-established low shrinkage methanol synthesis catalyst. This provides improved in-service strength and higher activity when compared to equivalent products of larger size pellet dimensions, particularly at temperatures where diffusion limits methanol formation >250°C (482°F).

Smaller pellets also tend to have superior selectivity toward methanol formation since the concentration of methanol within the smaller pellets is decreased, preventing the methanol reacting further.

The low shrinkage of KATALCO 51-91 is particularly well suited to radial flow converter designs, such as the JM Radial Steam Raising Converters (R-SRC), utilised in the BALANCE METHANOLTM flowsheet, ensures maximum vessel utilisation and more uniform gas distribution after reduction.

The benefits of KATALCO 51-91 have been realised by some of the world's largest methanol plants enabled by JM R-SRC technology.

KATALCO 51-92 is the next generation product which employs JM’s newest, patented promoter technology. This additionally achieves greatly improved resistance to deactivation by thermal sintering, further extending the useful operating life of the catalyst.