Dimethyl ether (DME) is a clean-burning, non-toxic fuel with similar properties to liquified petroleum gas (LPG) that can help accelerate the energy sector’s decarbonisation.

As a gas, DME is non-greenhouse, degradable, and releases significantly less NOx and particulate emissions than fossil liquid fuels in combustion engines at a parallel efficiency.

It offers ease-of-storage and transportation as a lightly pressurised liquid, providing a portable, low-polluting fuel solution for homes and industries with limited access to other sources of energy.

Producing dimethyl ether sustainably

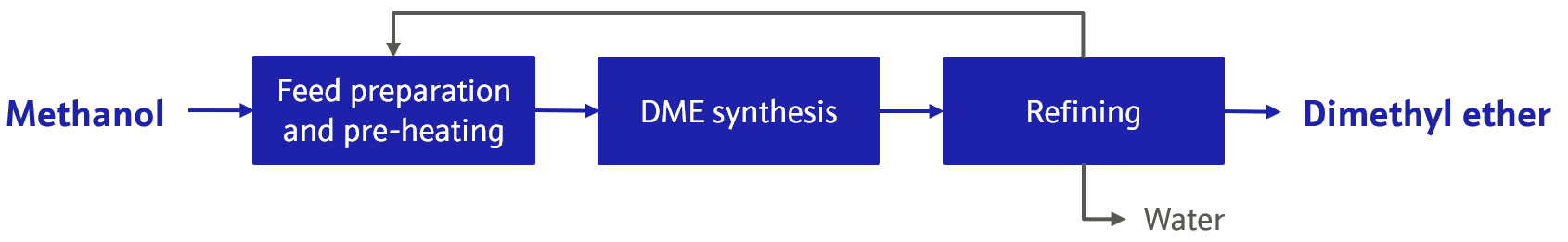

JM licenses a dimethyl ether production process from methanol that is simple, reliable, and has been commercially proven.

Our dimethyl ether production technology can use methanol obtained from biomass, waste or CO2, enabling the generation of renewable and recycled carbon DME.

This results in a lower carbon footprint fuel that can be blended with, or replace LPG and other high-carbon fossil fuels, helping decarbonise the transport sector as well as homes and businesses not connected to the gas grid.

Our DME production technology

Johnson Matthey’s commercially proven DME technology produces highly-pure dimethyl ether from methanol with high feedstock efficiency, achieving 96% yield and over 99.95% DME purity. Backed up by our long-standing experience in methanol, it is a simple, efficient and reliable solution.

Our DME technology uses the catalytic dehydration of methanol in the vapour-phase and can be integrated with any of our methanol flowsheets. When bolted onto our eMERALDTM, biomass, waste, or off-gas to methanol flowsheets, it enables the production of renewable and recycled carbon DME.

To discover how we can enable your high-purity dimethyl ether production, get in touch so we can learn more about your project requirements.