Environmental oxidation process

Environmental concerns about industrial emissions to air and water have been continually growing. In response, Johnson Matthey has targeted key issues by applying our expertise in catalysts and catalytic technology.

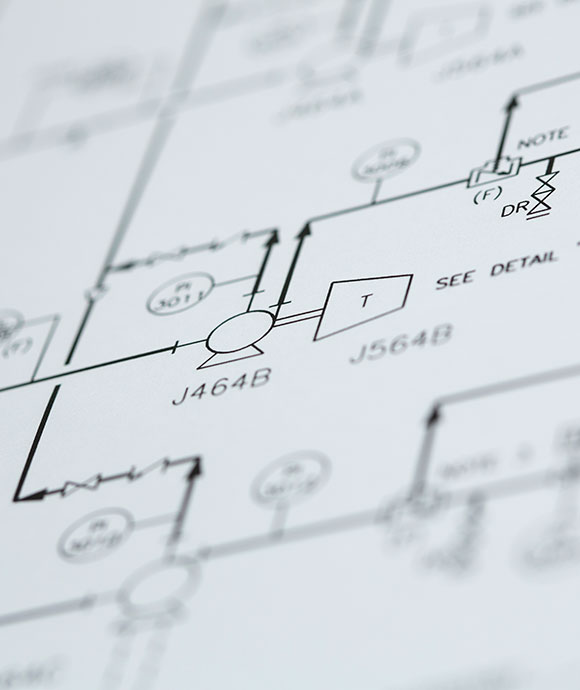

Johnson Matthey's range of fixed bed catalysts technologies is designed to treat a wide range of gaseous and liquid streams. In the core process, a catalyst converts sodium hypochlorite to brine and a highly reactive oxygen atom, which enhances the oxidation of organic contaminants in waste streams.

Our range of fixed bed catalyst technologies is designed to treat a wide range of gaseous and liquid streams. No competitor can rival its combination of robustness, fit-and-forget operation, economy, effectiveness and environmental compatibility. Yet these technologies can be easily combined with, as well as replace, existing systems.

- COD destruction, removing organics from aqueous systems - ACCENTTM technology

- Hypochlorite destruction, destroying waste hypochlorite streams - HYDECATTM technology

- Odour removal, removing odours and low level VOCs from air streams - ODORGARDTM technology

- VOC destruction, removing a broad variety of volatile organic compounds in industrial processes - PURAVOCTM technology.