#1

olefin to oxo chemicals technology

52

plants licensed

50+ years

of experience

Meeting market demand for oxo alcohols

LP Oxo℠ Technology, from Johnson Matthey and Dow Global Technologies, LLC, is the world’s leading process to manufacture oxo alcohols and butyraldehyde from olefins. It is a smart and versatile solution that enables you to easily and profitably produce most oxo chemicals from a range of feedstocks.

Using the LP Oxo℠ Process, you will achieve high feedstock efficiency at mild operating conditions. Enabled by a simple flowsheet and superior hydroformylation catalyst system, the process minimises equipment usage, lowering investment costs and reducing overall operating expenditure (OPEX).

JM also provides solutions designed to maximise the efficiency of your current processes. Drawing on our industry-leading knowhow, our technology can boost oxo alcohol plant performance and capacity at existing LP Oxo℠ plants.

A modular, tailored technology for oxo alcohol production

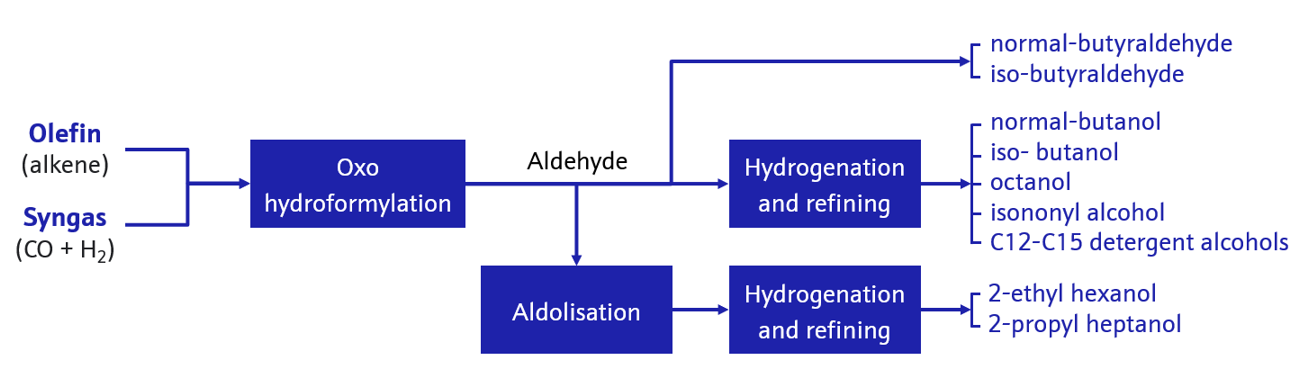

Hydroformylation, or oxo synthesis, is an important industrial process that forms the first step in oxo alcohol and chemical production. During the reaction, an aldehyde is formed by reacting an olefin (alkene) with syngas (CO and H2). The LP Oxo℠ Process uses a rhodium-based hydroformylation catalyst, which enables low pressure operation, high efficiency and a simple configuration for your oxo alcohol plant.

The intermediate aldehyde is then converted into an oxo alcohol by hydrogenation. This happens in the liquid phase, which eliminates the need for a recycle compressor and makes the reactor smaller and simpler, saving you cost and space.

Larger aldehydes can be obtained by adding two aldehydes together in an intermediate aldolisation step. We use it to produce 2-ethyl hexanol (2EH) and 2-propyl heptanol (2PH).

LP Oxo℠ Process is the key to global oxo alcohol demand

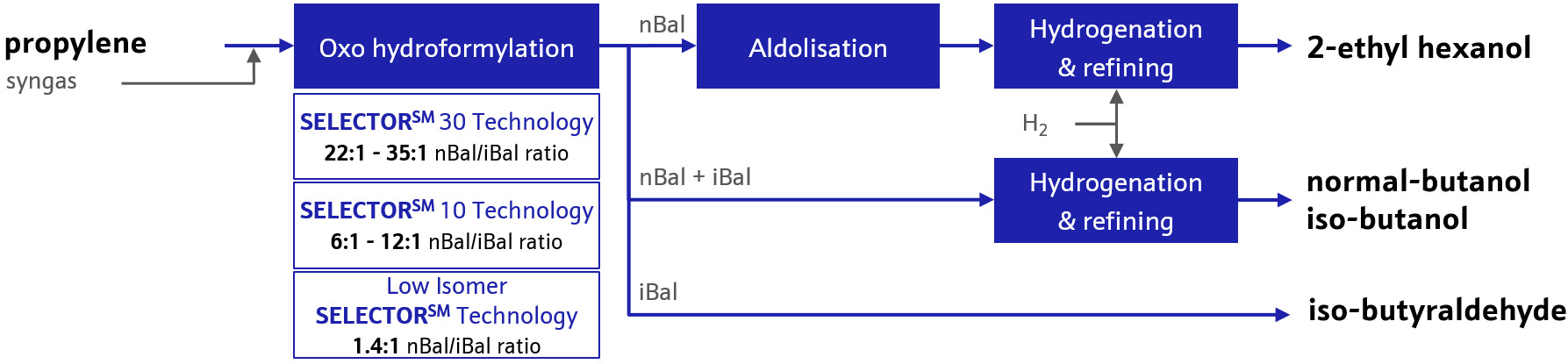

Hydroformylation of propylene

Normal-butanol (n-butanol), 2-ethyl hexanol (2-EH), iso-butyraldehyde (iBal) and iso-butanol (i-butanol) - all key oxo alcohols - can be produced from the hydroformylation of propylene via a mixed butyraldehyde stream.

With our range of SELECTOR℠ Technologies, we can tailor the ratio of normal- to iso-butyraldehyde (nBal to iBal) in the mixed aldehyde stream for every project.

This flexibility allows you to meet market demands by achieving specific yields for each oxo alcohol product.

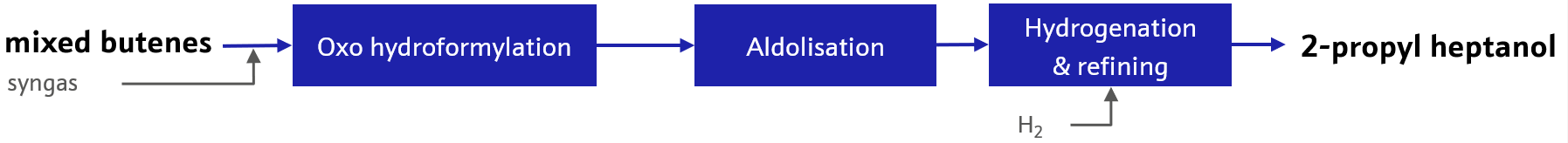

Hydroformylation of mixed butenes for 2-propylheptanol (2PH) production

The LP OxoTM Process can transform low-value mixed butene streams into high-value 2-propyl heptanol (2-PH).

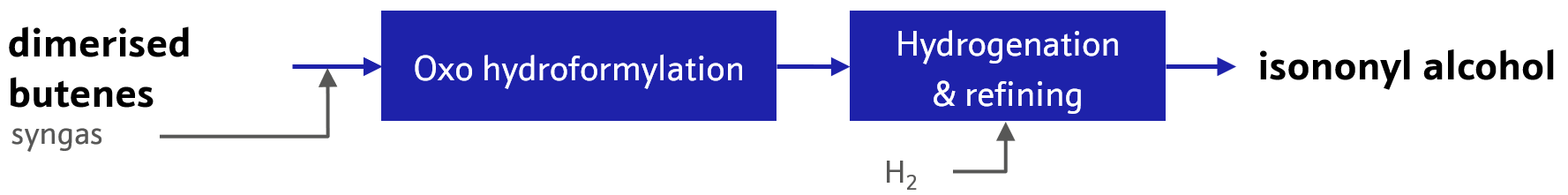

Hydroformylation of octenes for isononyl alcohol (INA) production

With the LP OxoSM Process, you can produce isononyl alcohol (INA) by hydroformylation and hydrogenation of mixed octenes, which are typically dimerised butenes.

Hydroformylation of olefins for octanol production

C7 olefins from Fischer-Tropsch synthesis can be used to make octanol with the LP OxoSM Process.

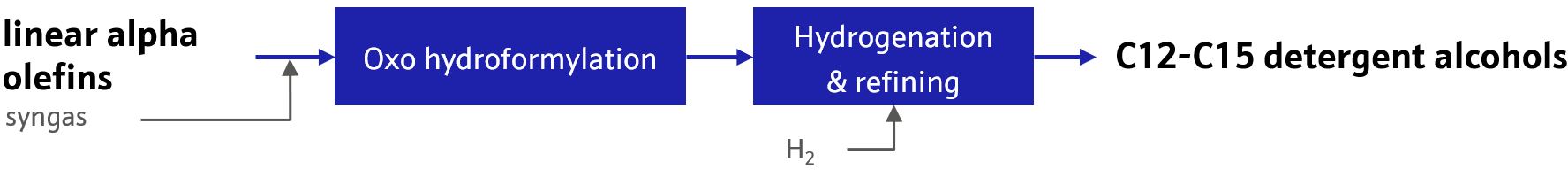

Hydroformylation of linear alpha olefins for detergent alcohol production

The LP OxoSM Process can produce a range of C12-C15 detergent alcohols using linear alpha olefins as a feed

Optimise your oxo alcohol production with LP Oxo℠ technology for hydroformulation

- Achieves higher feedstock efficiency and reduced by-product output under mild operating conditions, offering your oxo alcohol plant low operating costs and enhanced safety.

- Provides you with a wide range of options to tailor the process to production goals.

- Achieves a high-quality oxo alcohol output for both polymer and chemical-grade propylene feedstocks.

- Uses a simple hydroformylation catalyst management system that drives high uptimes.

- Reduces capital expenditure and plot requirements due to less and smaller equipment.