CompactSCR NOx control systems

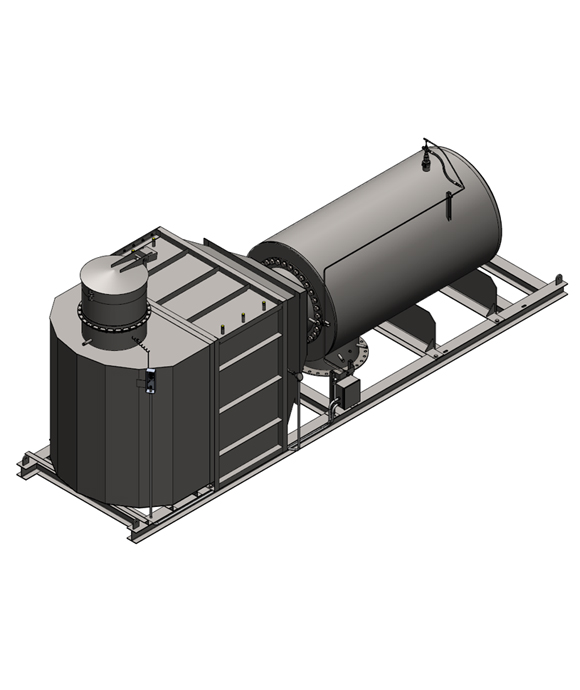

JM's CompactSCR® NOx control technology offers highly efficient, factory assembled, single-lift systems for NOx emission control from stationary sources.

Our CompactSCR systems are designed and engineered to enable ease of installation in a single-lift process and ease of operation including urea mixing (which ensures efficient and effective conversion of NOx over the JM SCR catalyst).

Delivering value

JM’s CompactSCR systems are guaranteed and:

- They are designed to achieve high NOx emission conversion rates in the very small footprint.

- The urea injection and all air line systems and mixing sections are built into the reactor.

- They reduce >95% of NOx from small to medium sized diesel and gas engines (up to 4500kW).

- They achieve high NOx, CO and hydrocarbon conversions with low NH3 slip.

- They are factory assembled for ease of field installation.