HTX platinum thermocouple

- Lasts 400 times longer than standard thermocouple wire

- Meets IEC 60584-1:2013 class 1 tolerance

- Available commercially

Our exceptionally strong HTXTM platinum thermocouple wire withstands the most demanding applications. Available globally as type R and S, we can manufacture it in any diameter down to 0.03mm. And with scale up and process capability tests completed, HTX is available commercially to meet your demands.

Superior strength for reliable measurements

We’ve developed a stronger platinum leg to our thermocouple wire by microalloying zirconium with the platinum to stabilise the grain boundaries, which prevents the formation of bamboo structures.

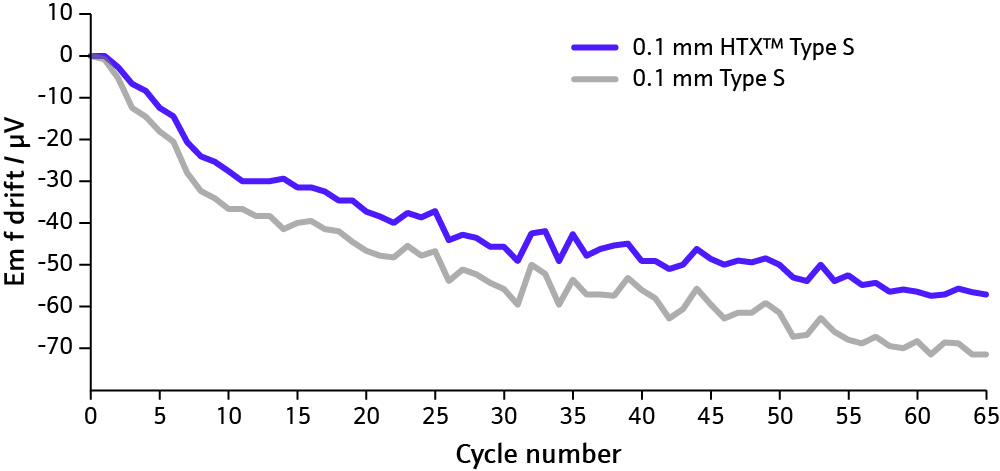

Containing the grains gives it outstanding strength; it lasts up to 400 times longer than standard thermocouple wire, offering a reliable temperature reading in harsh environments. We’ve proven this through accelerated lifetime testing, applying high loads at high temperatures to the wires. It also shows exceptional measurement accuracy, meeting IEC 60584-1:2013 class 1 tolerance. And with improved drift properties, it maintains this accuracy for longer. Independent trials at the National Physical Laboratory (NPL) have confirmed HTX wire has a better EMF output stability than conventional thermocouples, with reduced drift during thermal cycling tests.

Applying our expertise

Our customers have been seeking a high strength platinum thermocouple wire for harsh conditions, having found the pure platinum limb of type R and S thermocouples fails earlier than the alloyed limb, with a bamboo structure forming.

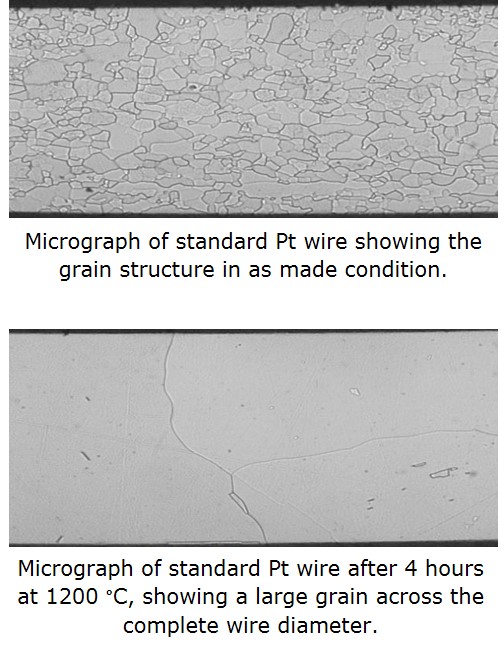

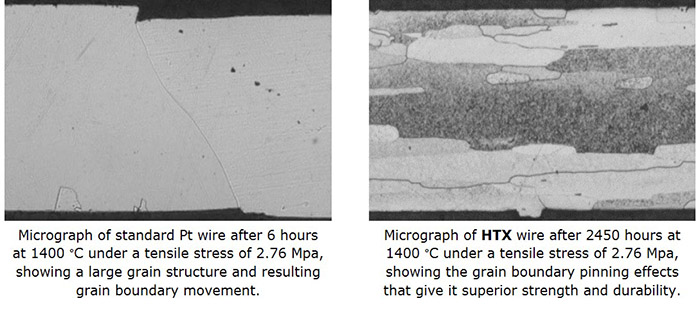

The bamboo structure is the result of grain growth. When individual grains in the wire occupy the complete wire diameter, the wire becomes a chain of grains linked by transverse grain boundaries. These boundaries are points of weakness. They are easily displaced or separated, causing a circuit break and stopping the temperature reading.

We know our customers need the wire to have two key properties: working at high temperatures, but without significantly changing the electrical properties of pure platinum. So we put our knowledge to the test.

Through extensive research and development, we trialled several routes to restrict the grain growth. We found a solution in microalloying zirconium with platinum, which oxidises in situ. These zirconium oxide particles enhance the wire by:

- Increasing the yield stress.

- Restricting grain growth by grain boundary pinning at high temperatures.

- Being electrically neutral so limiting the effect on the EMF.

HTX performance

High temperature durability

We’ve tested HTX wire under extreme conditions to ensure it can give you superior durability. During stress testing it maintains excellent functionality after 2,450 hours at 1400°C with 400psi tensile loading. These micrographs show that under the same tensile loading per unit area, standard platinum thermocouple wire forms a bamboo structures and fails after just six hours.

Consistent accuracy

In terms of accuracy, both type S and type R thermocouples with HTX wire repeatedly demonstrate IEC 60584-1:2013 class 1 performance. And while meeting ASTM E230 standard tolerances, they’re also within ASTM E230 special tolerances at high temperatures.

Minimal drift

Knowing that microalloying zirconium with platinum doesn’t affect the electrical properties of the thermocouple, we wanted to validate its performance. With funding from innovate UK, we used independent trials at the National Physical Laboratory (NPL) to verify the drift properties. Using extremely precise equipment and in situ calibration, we ran repeated thermal cycles up and down, measuring EMF output at the Co/C freeze point (1324°C) to track drift. Over a 900 hour thermal cycle, both HTX type R and type S wires are more stable, with standard thermocouple wire drifting at a faster rate. And we saw similar trends under a more extreme temperature range.

The combination of a lower drift with the higher strength properties makes HTX thermocouple wire a longer life product.

Get in touch