Precious metal recovery

We offer innovative solutions for effective cleaning of plant components through onsite and offsite aggressive and non-aggressive techniques. This recovery of platinum group metals (pgms) lost downstream from the gauze catalyst improves the boilers thermal efficiency. Typically, 20% of metal losses are recovered.

We collaborate with skilled professionals globally to offer these cleandown services; in some parts of the world this is through our longstanding partnership with RS Bruce. They will plan the cleaning with the plant operator to minimise disruption and maximise metal recovery.

Mild chemical treatment

This is used for specific components within the working plant. The treatment solution is used to immerse or spray the components, resulting in a pgm bearing oxide being removed.

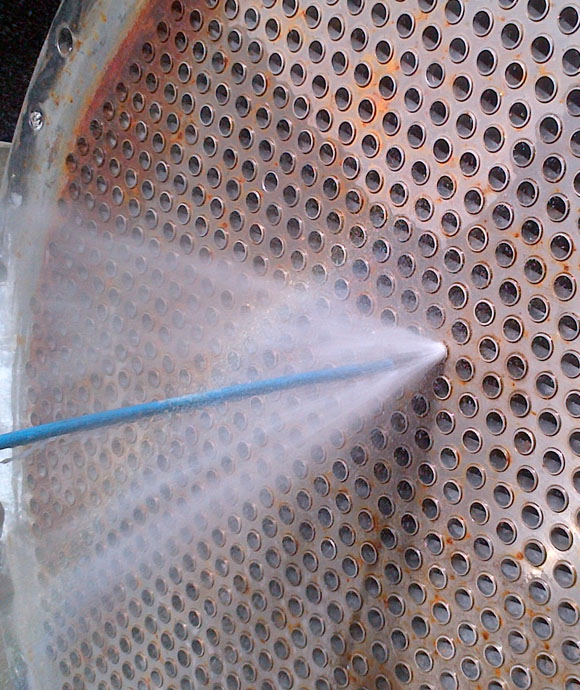

High pressure jetting

This is an efficient and cost effective method for removing a pgm bearing oxide from tube side components. It uses demineralised water between 5,000-20,000psi (1,000-1,400bar) through specifically designed flexible lances and jet nozzles.

Aggressive cleaning

Specifically used on decommissioned plants and out of service components, it ensures maximum recovery of precious metal oxides. Using controlled and proven processes this aggressive method can be carried out by our experienced specialists on-site or at specialist facilities.

Get in touch