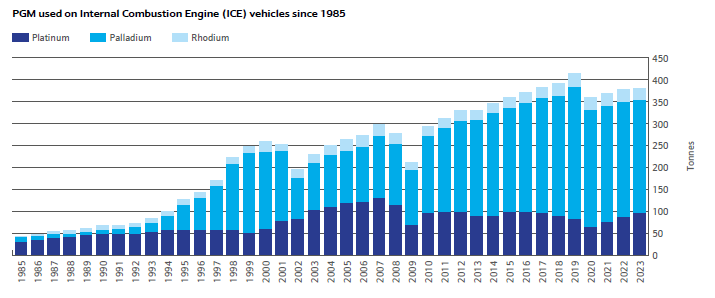

Platinum group metals (PGMs) are among the most highly recycled materials in the world, with recycling rates in some applications exceeding 95%. Over the past 50 years automotive and industrial use of the PGMs has grown dramatically. Meeting this rising demand would not have been possible without circularity.

Recycling and the case for circularity

For decades industries have followed a linear model of consumption where critical resources are extracted, used to produce goods, and then disposed of as waste at end of their life. With growing pressure on finite resources and the need for a more sustainable future, this is no longer an option - a shift to a circular model of consumption is a must.

Recycling plays a pivotal role in keeping materials in use, reducing waste and reliance on virgin resources. By recovering and reprocessing materials, industries can secure future supply and build more resilient and sustainable supply chains.

How PGM circularity works

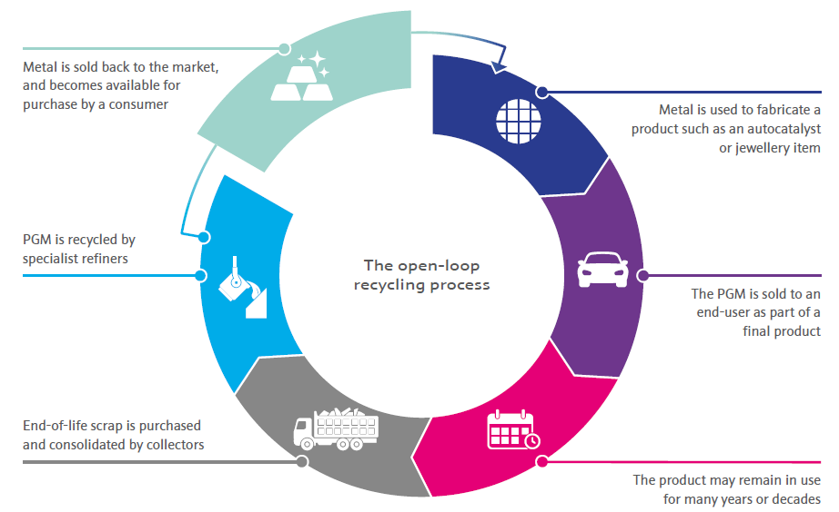

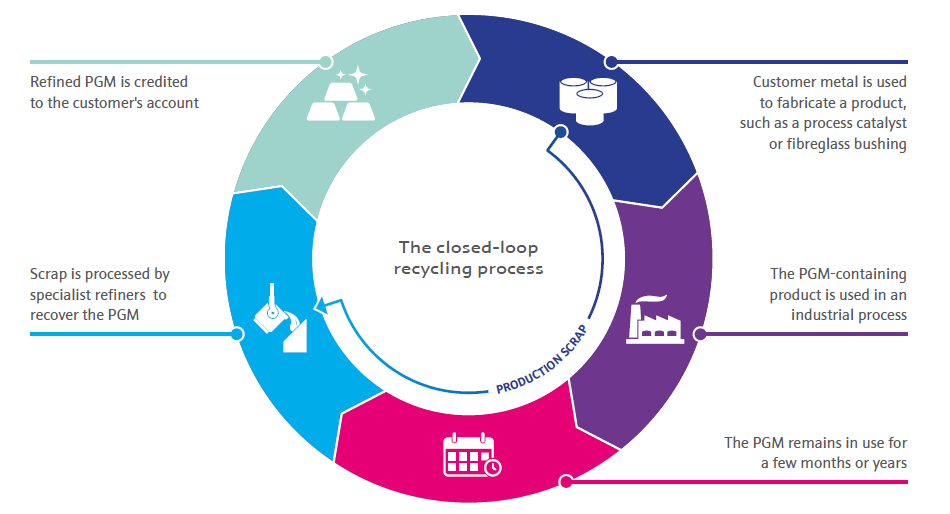

Recycling supports PGM availability in two ways: through open loop and closed loop recycling.

Open-loop recycling

The original purchaser of the metal does not retain control of the PGM, so the metal is available to the market once recovered. It contributes to market supply and helps bridge the gap between supply and demand.

Closed-loop recycling

Metal is retained within the same application by the same owner. For example, PGM recycled from spent chemical catalyst used make fresh catalyst to replace it. Because the net amount of metal in use has not changed, the ‘returned’ metal does not count as market supply, but it reduces the need for fresh metal to be purchased and therefore makes demand more sustainable.

Because the PGMs are highly recyclable and retain the same properties once recycled, the 'urban mine' of metal currently in use will continue to be a valuable source of these metals for many decades. In fact with regulatory support to ensure PGMs in end-of-life equipment are collected as efficiently as possible, even more could be recovered in future.

The largest secondary supply of PGMs today is from catalytic converters. With the lifetime of internal combustion engines remaining on the road for 15 to 20 years and beyond, there will be a continuous source of PGMs for some time.

In jewellery applications, stocks exist mainly of platinum stocks and are held by consumers. Recycling of old jewellery in China and Japan happens more routinely than for Western regions.

PGMs used in industrial applications are a form of stock currently circulating in a closed loop. As this PGM has been purchased for a particular use, it will only become available in the future should new technologies or product demand change. Petroleum refineries and petrochemical plants are an example of large accumulations of PGMs that could be a potential source of PGMs for future applications.