Catalyst coated membrane (CCM) for PEM electrolysis

CCMs are the heart of PEM electrolysers, facilitating the electrochemical reactions to take place and enabling hydrogen to be produced. At Johnson Matthey, we develop and manufacture high-performance CCM technology at scale. Working closely with our customers, we deliver a design that meets their needs both today and in the future. In addition, as the world’s largest secondary refiner of platinum group metals, we are committed to the creation of an efficient recycling system to help unlock future capacity and support a sustainable energy transition.

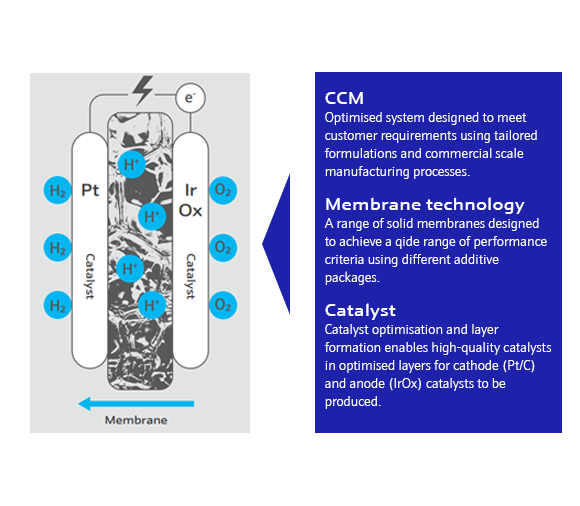

How do CCMs work?

CCMs consist of precisely structured catalysts typically platinum (cathode) and iridium (anode) that are applied to solid membranes in a way which maximises hydrogen production.

Water flows into the CCM, where an iridium catalyst uses electrical energy to break water molecules into oxygen, protons and electrons. The electrons are driven through the external circuit and protons then cross the membrane. A platinum catalyst puts the protons and electrons back together to form hydrogen.

System optimisation

The key to achieving an optimal system is not just combining the most advanced individual components but optimising each component and the way the CCM is assembled based on the end use operating requirements, balancing the trade-offs and design choices that exist for electrolyser owners and operators. It is also very important that circular economy principles are incorporated into the system design enabling recycling and the ability to reuse as much of the electrolyser as possible. In this way, the carbon footprint created by the manufacture of electrolysers themselves can be minimised.

To optimise your electrolyser system talk to JM today.