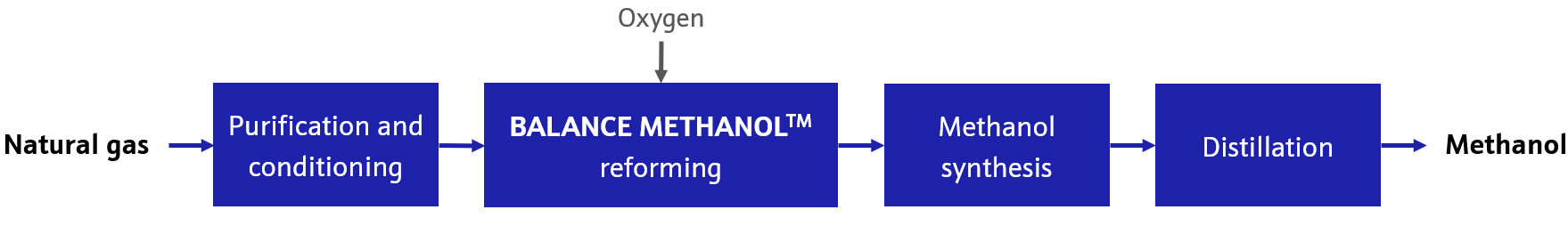

Our BALANCE METHANOL™ process is a robust technology for medium to large capacity plants which delivers consistent, high performance and which is used today in the most energy efficient methanol plants in the world. By splitting the reforming duty between a steam methane reformer (SMR) and an autothermal reformer (ATR), the process can be easily adjusted for a wide range of natural gas compositions.

The technology uses Johnson Matthey’s well proven high-efficiency methanol synthesis loop which enables sustained, high conversion and production rate through catalyst life, minimising the natural gas requirements and reducing the size and cost of the more expensive up-stream equipment items.

With our latest development, we have taken the design to the next level by reducing the plant CAPEX and direct CO2 emissions even further.

- Lowest natural gas usage and direct CO2 emissions when compared to alternative market-leading combined reforming processes.

- Well proven performance - over 50 SMRs, 25 ATRs and secondary reformers, and 35 high-efficiency methanol converters commissioned, in continuous, safe, and profitable operation.

- Sustained methanol production through catalyst life.

- Very few proprietary equipment items required: ATR burner, bypass injector and converter distributor.

- Demonstrated world-class reliability.