Johnson Matthey’s methanol processes are designed to combine our most efficient technology with cutting-edge catalysts and absorbents. This includes our advanced methanol catalyst, to maximise plant performance and minimise operating costs.

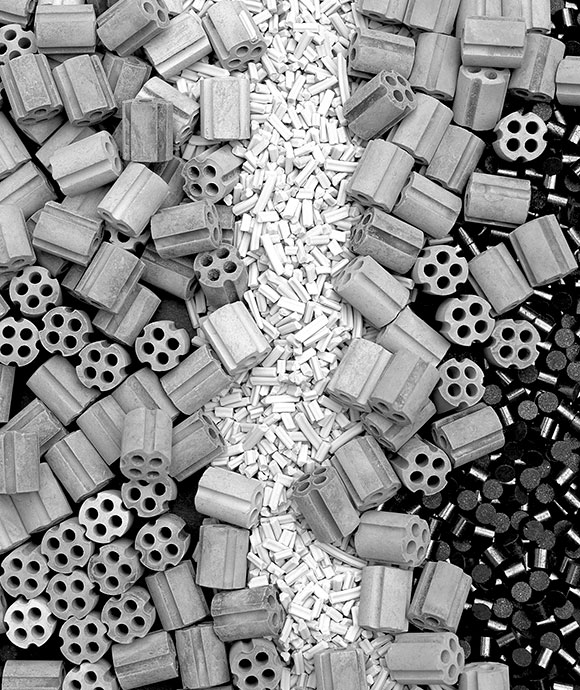

Our state-of-the-art KATALCO™ catalysts and absorbents, known for their exceptional quality, deliver enhanced process performance, unmatched reliability in service, and an extended lifespan. With Johnson Matthey’s methanol catalysts, you can achieve superior results in methanol production and ensure your plant operates at peak efficiency.

Our methanol flowsheets require 3 key stages:

Feedstock purification

An effective feedstock purification system is an essential step in the production of methanol and the increasing use of alternative feedstocks bring new contaminant challenges.

Our wide range of methanol absorbents will ensure downstream catalysts and equipment are protected from harmful contaminants. This will prolong catalyst life, minimising changeouts and maximise your plant’s throughput and profitability.

Reforming

Johnson Matthey’s KATALCO reformer catalysts allow operators to process a wide range of feedstock compositions, extend turnaround cycles and prolong reformer tube life.

Methanol synthesis

Our KATALCO 51-series of methanol synthesis catalysts are pivotal to our methanol technologies. Over the years the KATALCO 51-series has been optimised to give increasing activity, selectivity, and stability.

As the leading methanol catalyst supplier, our focus is delivering the best in the world performance for our customers.