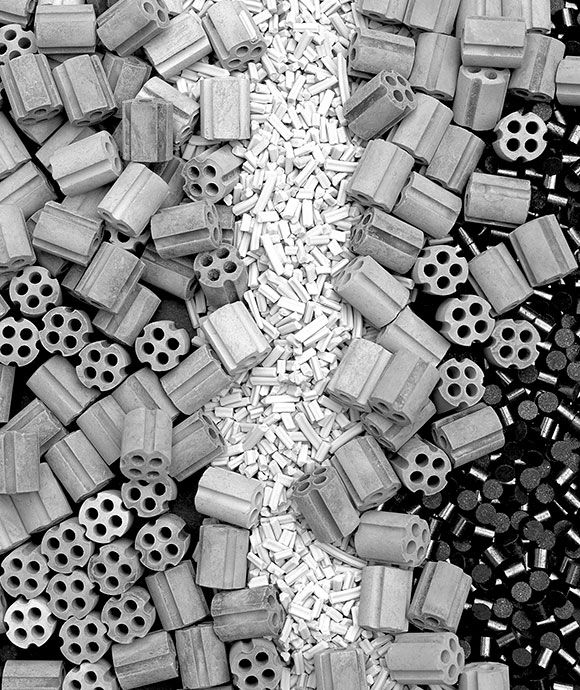

Methanation catalysts

Methanation is the reaction by which carbon oxides and hydrogen, catalysed by nickel, are converted into methane and water. In industry, there are two main uses for methanation: to purify synthesis gas (i.e. remove traces of carbon oxides) and to manufacture methane.

Methanation for synthesis gas purification

Methanation is the final stage in the purification of synthesis gas. Most modern ammonia plants plus some older hydrogen plants use the simple and convenient methanation reaction to remove traces of carbon oxides from the process gas.

Johnson Matthey manufactures a range of oxidic and pre-reduced KATALCOTM methanation catalysts for ammonia and hydrogen production. The high activity of the KATALCO series catalysts means that methanation can be performed at lower temperatures than is typical, improving the energy efficiency of the process.

Methanation for SNG

In substitute natural gas (SNG) manufacture, carbon oxides and hydrogen from alternative hydrocarbon sources are converted into methane. Johnson Matthey offers the CRGTM methanation catalyst range for this duty.

CRG catalysts provide good thermal stability and resistance to residual poisons in the gas to achieve a long life while giving the flexibility to operate over a wide temperature range, resulting in high efficiency and heat recovery.

Methanation for ethylene production

Hydrogen produced as a by-product of ethylene production contains 500 to 5,000 ppm carbon monoxide. Before this can be used in reactors containing palladium or platinum-based catalysts, the concentration of carbon monoxide must be reduced to less than 10 ppm. This can be achieved via methanation.

Johnson Matthey manufactures a range of oxidic and pre-reduced KATALCO methanation catalysts for ethylene production.