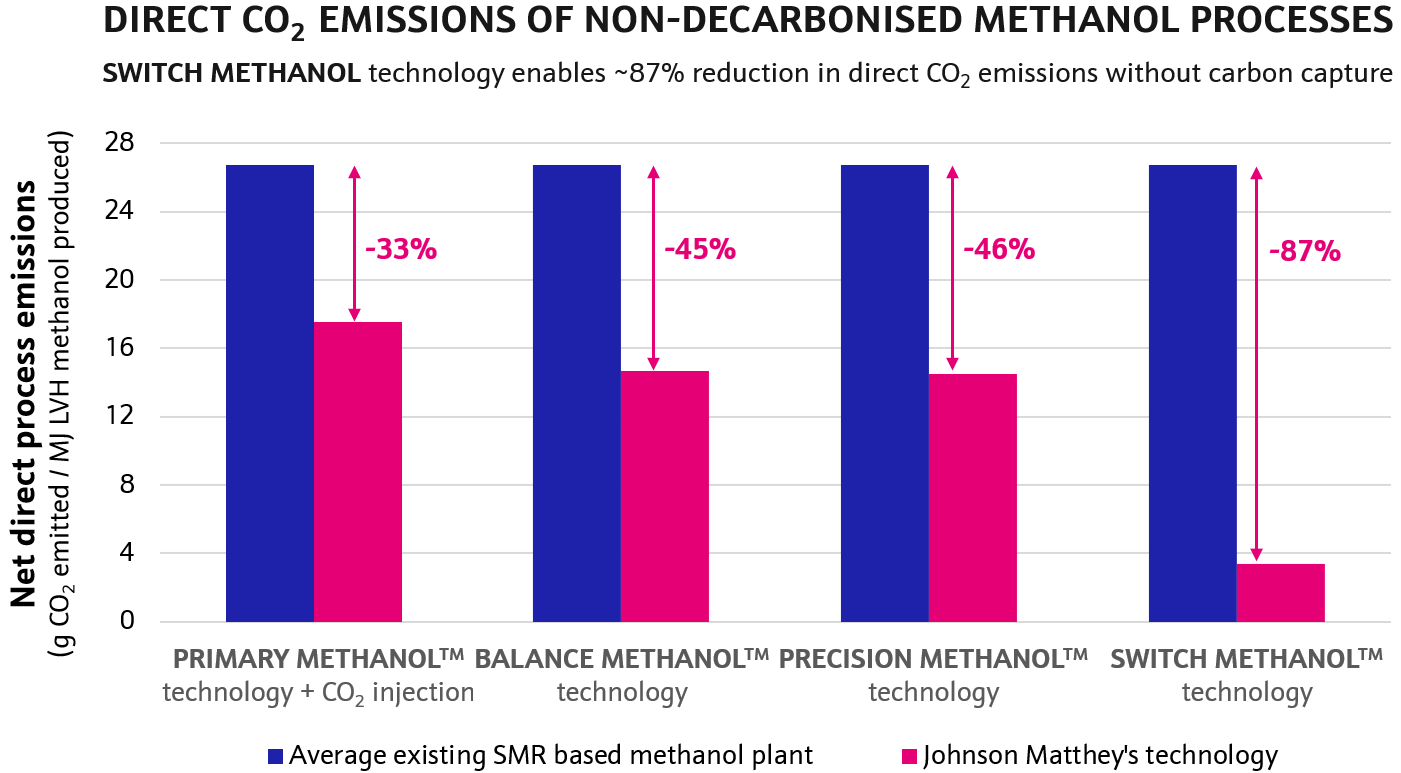

Johnson Matthey’s award-winning SWITCH METHANOL™ process delivers minimal direct CO2 emissions without the additional investment, running costs and complexity of carbon capture. It is ready to receive renewable electricity and it enables methanol producers to meet their sustainability goals as we transition to a low-carbon economy.

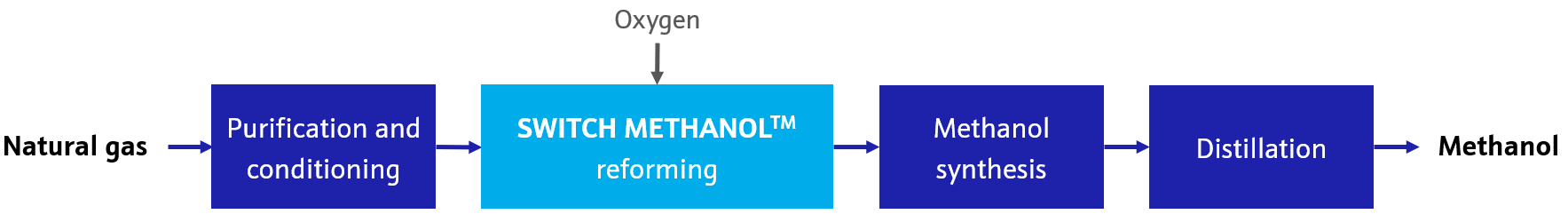

This break-through solution uses our unique Gas Heated Reformer (GHR) and Autothermal Reformer (ATR) in tandem to recycle all the high-grade heat directly back into the process. Further feedstock and energy savings are achieved in the methanol synthesis loop, which delivers high efficiency and heat recovery by using simple and low-cost tube cooled converters (TCC).

The result is a fuelless reforming process with minimised natural gas consumption, scope 1 emissions and water usage that can be electrified.

The SWITCH METHANOL technology is underpinned by 40 years of rigorous development and is a proven and bankable solution which is being selected for the leading low carbon projects of the future.

- Minimised Scope 1 CO2 emissions without carbon capture

- Readiness for electrification

- Lowest natural gas usage

- Lowest water requirements

- Similar CAPEX and plot area than a non-decarbonised plant based on autothermal or combined reforming.

- No PGM catalysts