#1

technology from maleic anhydride

1.9 million

tonnes/year licensed capacity

30 Years

of profitable operation

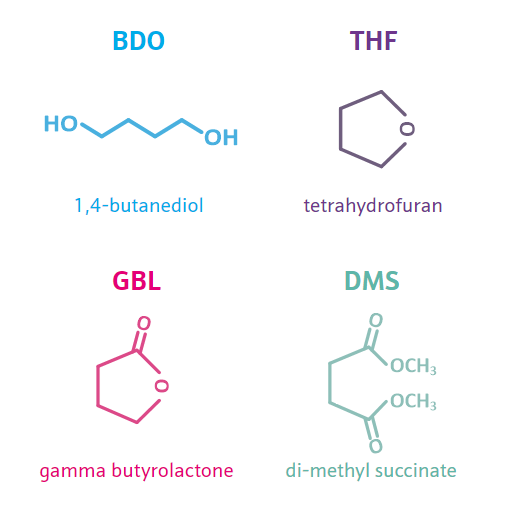

Butanediol (BDO) and its co-products are highly versatile chemical intermediates. From engineering plastics and clothing fibres to industrial solvents, many essential products are made from BDO and its derivatives.

Butanediol production is also becoming increasingly significant to manufacturing as addressing plastic pollution and climate change becomes more important.

-

BDO is a key ingredient in the production of biodegradable plastics polybutylene adipate co-terephthalate (PBAT) and polybutylene succinate (PBS).

-

Di-methyl succinate (DMS) produced from maleic anhydride enables an economic route for the world-scale production of high-quality PBS.

-

Gamma-butyrolactone (GBL) is used to produce n-methyl pyrrolidone (NMP), the go-to solvent for manufacturing lithium-ion batteries for electric vehicles.

Enable profitability and flexibility with Johnson Matthey’s butanediol technology

Johnson Matthey’s butanediol production technology enables the generation of BDO, GBL and THF from maleic anhydride in a single reaction train and in flexible quantities. Furthermore, with our optional DMS unit, we can also enable the low-cost production of highly pure DMS, thereby providing a fully integrated and economical solution to high-quality PBS.

Our highly integrated flowsheet allows producers to tailor their product split to market conditions, ensuring they can produce premium-quality BDO products with reduced CAPEX, OPEX and a smaller carbon footprint.

Johnson Matthey’s technology can also utilise bio-based succinic acid as an alternative feedstock to maleic anhydride, facilitating our customer’s transition to more sustainable butanediol production.

As the leading maleic-based butanediol technology licensor, we have a deep understanding of the BDO chemistry. Our expertise enables us to precisely control the complex process and deliver high-quality, premium BDO and DMS for our customers.

Our BDO technology delivers:

-

Flexible production of BDO, THF, GBL and DMS in a single plant.

-

Highly integrated process resulting in less CAPEX and OPEX.

-

>96% product yield.

-

Mild, safer operating conditions.

-

Highly pure DMS ideal for premium quality PBS production

-

Significantly lower carbon intensity than alternative routes to BDO.

-

High-performance and low-cost, base metal hydrogenolysis catalyst.

-

Non-acidic hydrogenolysis environment which enables the use of low-cost materials of construction.

-

Simple catalyst management thanks the use of heterogeneous catalysts which stay in their respective vessels and don’t need separation.

-

Premium product purity achieved thanks to 30 years of technology and chemistry know-how.

-

Proven track record of delivering high quality, profitable product into the market.