Mercury-free

catalyst and technology

16

full loads of JM’s PRICATTM MFC into existing, primary commercial reactors replacing mercury catalyst

1.5 million

tonnes per year of new, mercury-free VCM to PVC capacity using JM’s technology and catalyst

Profitable and mercury-free vinyl chloride monomer production that protects the environment

Vinyl chloride monomer production (VCM) is the building block of polyvinyl chloride (PVC). This makes it one of the most important intermediates in the petrochemical industry today.

Currently, about a third of global vinyl chloride monomer production uses the hydrochlorination of acetylene over a mercury-based catalyst. The mercury losses from both the catalyst manufacture and VCM production cause considerable environmental damage to the air, water and land.

JM’s VCM technology uses an advanced flowsheet and high-performance gold-based catalyst, enabling your cost-competitive and efficient vinyl chloride monomer production without mercury.

High yield, long-lasting vinyl chloride monomer production with JM’s PRICAT™ mercury-free catalyst (MFC)

The process uses JM’s vinyl chloride monomer catalyst, PRICAT MFC (mercury free catalyst). PRICAT MFC is a highly selective gold catalyst that is three times more productive than mercury-based alternatives and achieves high acetylene-to-VCM conversion for significantly longer. The catalyst’s long life means high uptime and fewer changeovers to keep OPEX low, while the elimination of mercury from the process enables safer maintenance.

95% of the gold in PRICAT MFC can also be recovered and reused in fresh catalysts. This helps keep gold use low and improves the environmental impact of the overall VCM technology.

A simpler reactor design for your vinyl chloride monomer production

Johnson Matthey’s VCM technology includes our flowsheet which has been tailored around PRICAT MFC’s superior performance. This cuts down on your gold usage and provides you with a more cost-effective solution.

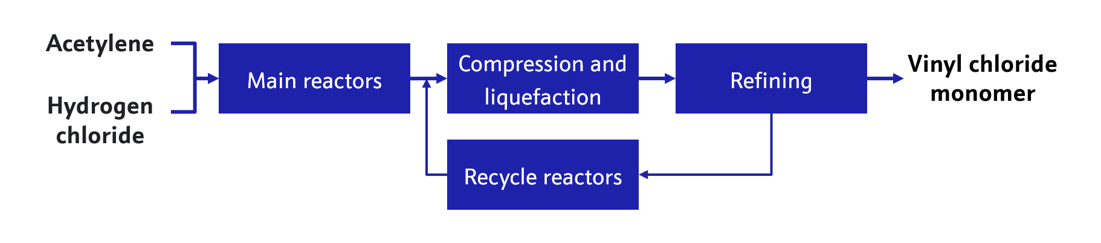

Our solution produces VCM from acetylene and hydrogen chloride in an anhydrous process which uses both main and recycle reactors. The bulk of the reaction is carried out by the main reactors, while the recycle reactors help the transformation of un-converted feedstocks into product. This feature of our VCM production process enables every reactor to operate at a high reaction rate, with less catalyst and without the need for full conversion.

You also no longer need many primary and secondary reactors in parallel, nor frequent catalyst change-outs with our technology. This results in mercury-free VCM production that only requires one-third of the catalyst and reactors than the traditional process, significantly saving you on CAPEX and gold usage.

Advantages of JM’s vinyl chloride monomer production flowsheet and catalyst combination

-

High feedstock efficiency, providing you with over 99% acetylene and over 98% hydrochloric acid conversion.

-

>99.98% VCM product purity, suited to manufacture high-quality PVC.

-

A cost-effective process requiring a similar investment to a traditional mercury-based plant, including the cost of gold.

-

An anhydrous non-corrosive environment, enabling the use of low-cost materials, thereby reducing CAPEX.

-

Generates low-pressure steam.

Use JM’s PRICAT vinyl chloride monomer catalyst in your existing plants to transition to mercury-free production

JM’s PRICAT MFC is also compatible with existing vinyl chloride monomer plants, where it can be directly loaded into the reactors to replace the mercury catalyst. This provides manufacturers with a drop-in, mercury-free solution to help transition away from mercury-based vinyl chloride monomer production.

JM’s gold-based PRICAT MFC catalyst for vinyl chloride monomer production from acetylene delivers:

- 18 to 20 months lifecycle at high conversion.

- Low precious metal losses: gold recovery and re-use into fresh catalyst.

- Compatibility as a mercury catalyst replacement at VCM plants with a cooling system designed for high temperature operation.

- A proven solution being used in commercial operation at acetylene to VCM plants that have partially or fully switched from mercury to mercury-free catalyst.