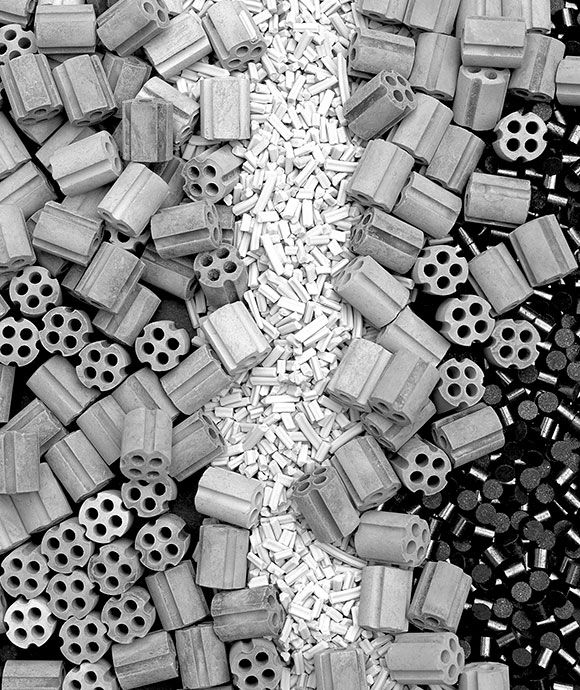

Reforming catalysts

Reforming is the most critical unit operation in an ammonia, methanol and hydrogen plant. The correct reforming catalyst is vital for achieving acceptable production rates, meeting efficiency targets and avoiding unplanned downtime.

Pre-reforming catalysts

Johnson Matthey has been associated with pre-reforming catalysts since the 1960s and offers CRG process technology and catalysts. Our catalyst range has been proven to be the most active and robust commercially available product on the market and extends across ammonia, methanol, hydrogen and GTL production.

Steam methane reforming catalysts

Steam-methane reforming (SMR) is the most critical operating unit in the ammonia, methanol, hydrogen and GTL production train.

- Johnson Matthey's combination of catalysts and services ensures optimal operation at all times.

- The choice of catalysts is unique in its ability to reform efficiently the full range of feedstocks from natural gas up to naphthas.

JM is home to a steam methane reforming catalyst range for ammonia, methanol, hydrogen and GTL production.

Autothermal reforming catalysts

Autothermal reforming (ATR) has the most arduous mechanical and physical requirements in the plant.

Johnson Matthey combines sophisticated computational fluid dynamics (CFD) techniques and process models to ensure the best performance from our state of the art range of catalysts.

Our ATR catalysts support ammonia, methanol, and GTL production.