90%+

reduction of CO, VOCs, formaldehyde and more

10+

years of continuous operation across many installations

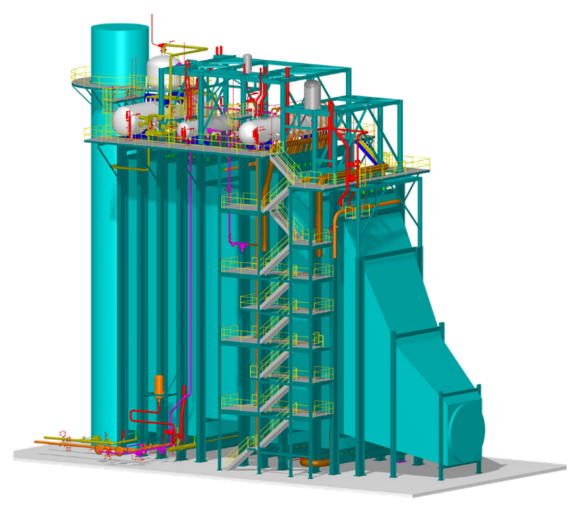

High performing gas turbine catalysts

Johnson Matthey has been setting the standard in gas turbine emissions control since pioneering the first oxidation catalyst in the 1970s. Today, our catalysts are trusted in some of the most challenging environments, delivering more than 90% reduction of carbon monoxide (CO), volatile organic compounds (VOCs), formaldehyde, and other harmful pollutants. In many installations, they have proven durable for over ten years of continuous operation.

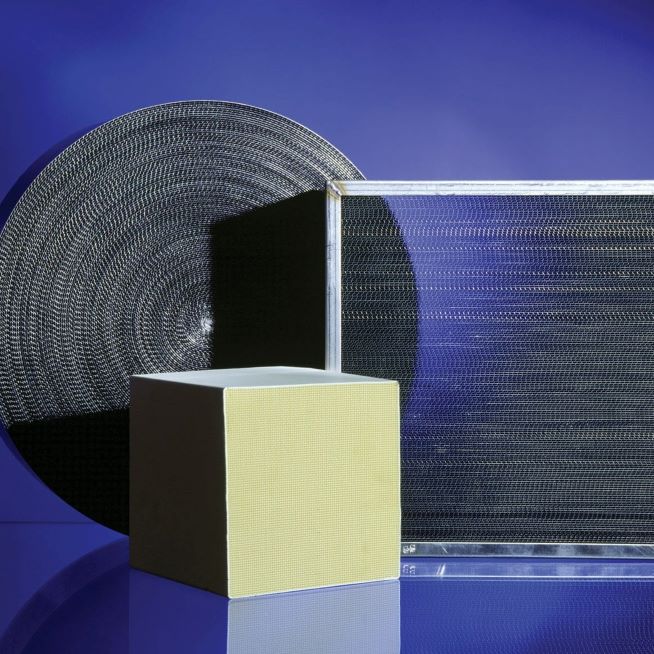

Backed by decades of catalytic expertise, our innovative advanced washcoat technology ensures superior performance and long-term reliability. Our oxidation catalysts, formulated with platinum group metals (PGMs), achieve maximum conversion efficiency across both simple-cycle and combined-cycle turbines.

The combination of high-activity catalyst formulations with a flow-through metal monolith design means customers benefit from the smallest catalyst footprint, lowest back pressure, and minimised side reactions such as NO to NO2.

Dependable catalyst technology for half a century

For more than 200 years, Johnson Matthey has been delivering science-based solutions. With over 50 years of leadership in environmental catalyst technology, we are the trusted partner for operators seeking proven emissions control.

Our CO catalysts combine unmatched activity with a compact, low-pressure-drop design to provide long-lasting, dependable performance. Customers worldwide rely on Johnson Matthey to help meet the toughest environmental regulations while ensuring operational efficiency.