Producing large volumes of clean hydrogen

Hydrogen today is predominantly made by conventional steam methane reforming of natural gas. The Hydrogen Council estimate the amount of hydrogen currently used globally to be eight exajoules sourced from refineries, to ammonia and methanol production. And with a growing population and as refineries demand additional hydrogen to upgrade heavier oil, these markets are only expected to grow.

In the future it's likely that we'll need to massively increase the production of hydrogen. It's now understood that to reduce the impact of climate change we must dramatically reduce CO2 emissions, requiring deep cuts across every aspect of life. Transitioning to low carbon energy will require many different solutions with a low carbon gas option a critical component in providing a robust, resilient system that is low cost and flexible. Of all the possible options available to us for decarbonised gas, hydrogen has the potential to have a game changing impact on climate change.

But if hydrogen is to play a role in reducing the impact of climate change, it will need to have lower CO2 emissions than current manufacturing processes. If hydrogen is to be made from natural gas it needs to be coupled with carbon capture and storage (CCS). To produce clean hydrogen cost effectively the products we want are hydrogen at high purity and pressure and CO2 at high pressure and purity to send for CCS. It is therefore more cost effective to [???].

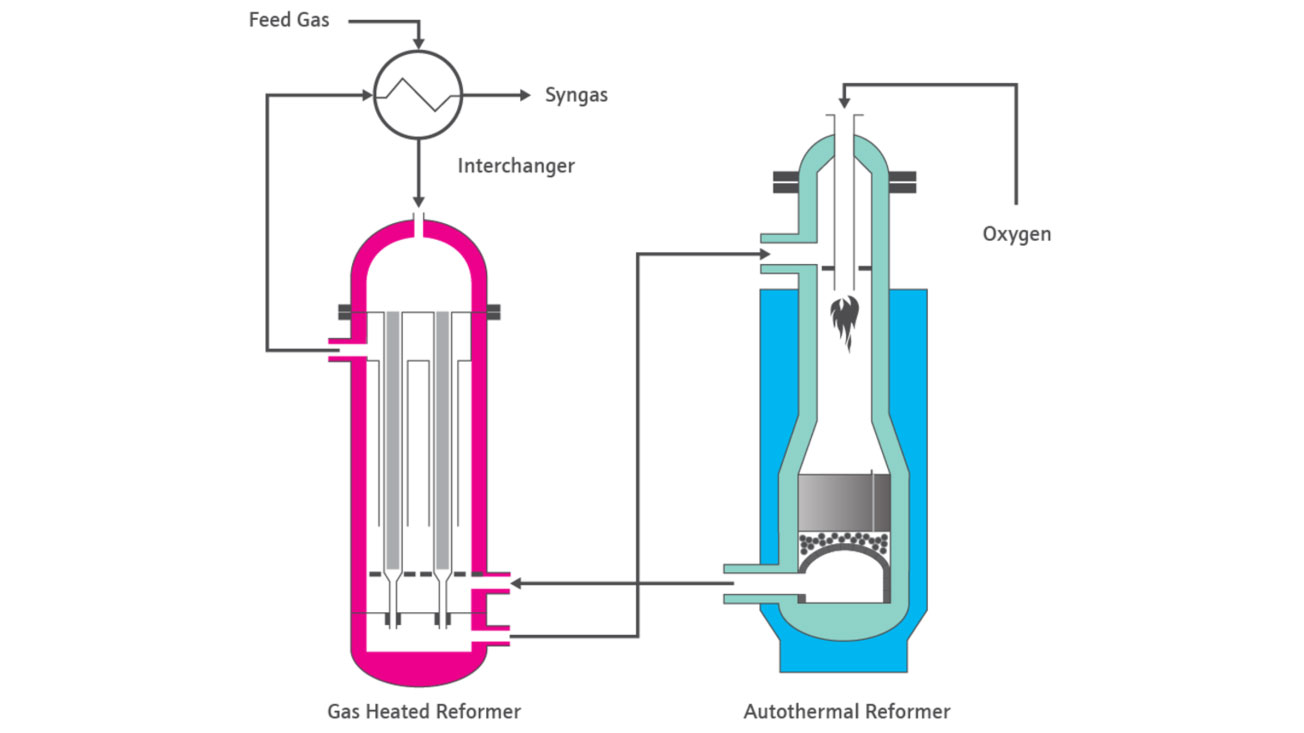

The main difference between our Leading Concept Hydrogen (LCH) solution and the conventional route to hydrogen using steam methane reforming (SMR) is that the energy to drive the reaction is provided by introducing oxygen to the reactor rather than burning fuel in gas burners.

The advantages of our scheme are:

- Heat is recycled at a higher quality than in an SMR flowsheet.

- The reforming reaction is conducted at a higher temperature which means more methane is converted to hydrogen.

- The vast majority of CO2 produced during the various reactions is contained within the process and can be captured at >95% using existing technology.

This month JM received a grant from UK Department of Business, Energy and Industrial Strategy (BEIS). This is to develop our understanding of the costs and performance for the proposed LCH solution under the Energy Entrepreneurs Fund Wave 6.

The information generated will inform BEIS on the potential for cost effective clean hydrogen production at large scale as part of their wider ambitions within the Clean Growth Plan. With ambitious policy over the next few years, the UK can continue to progress towards fulfilling obligations under the Climate Change Act.