Last year, JM won a £100K grant for the ‘Analysis for Innovators’ (A4I) competition to develop its HTX wire. The grant was used to assess the long-term performance of HTX wire, specifically thermoelectric stability, at the National Physical Laboratory (NPL) in London.

The data generated has demonstrated the benefits of HTX wire and the low risk associated with it, as required by the highly regulated nuclear and aerospace industries, where new products can be uncertain and costly.

HTX wire is one of the biggest innovations in the field of precious metal thermocouples and resolves the long-standing problem of short lifespan at high temperatures. It is a serious issue that not only adds significant cost to the users but could also affect efficiency of the processes. For some applications such as glass furnaces, the whole line needs to shut down to replace the thermocouples. In some other applications, most notably jet engines, thermocouple sensors are intentionally placed further away from the hottest parts of the engine even though it is less efficient to do so. The new development has got a real potential of improving the design of the end application.

HTX was developed by doping platinum with very small quantities of zirconium which is oxidised during processing to electrically neutral zirconia. Zirconia improves the high temperature strength of platinum wire by pinning the grain boundaries and restricting the grain growth but without affecting the EMF significantly. The result is a wire which lasts more than 400 times longer at high temperatures (>1200oC) than standard platinum and keeps the sensor in a very tight tolerance for longer.

Thermocouple measurements at NPL:

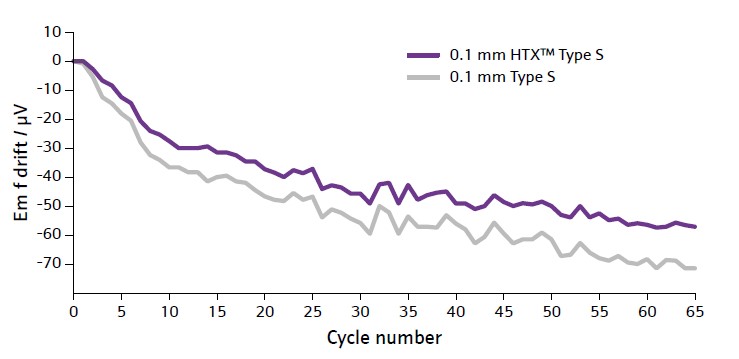

The trials at NPL, the UK’s national measurement institute, confirm that HTX has a better EMF output stability compared to conventional thermocouples. Using HTX wire reduces drift during thermal cycling tests showing that HTX thermocouples maintain their accuracy for longer.

A combination of conventional platinum thermocouples and HTX thermocouples were put through repeated thermal cycles, up and down through Co/C freeze point (1324oC ). The EMF output at the freeze point was measured and plotted against time.

Chart showing a reduction in EMF drift during thermal cycling trials. Source data available from NPL on request.

When comparing the difference in drift between HTX and standard Pt Type S and Type R, the EMF outputs are diverging. Standard thermocouple types are drifting at a faster rate than HTX.

Similar results were seen when the thermocouples were put under a more extreme temperature range. This combination of high strength and better EMF output stability offers a longer life product with lower drift.

For more information or to the obtain the source data from NPL, please contact Les Hutton, Product Specialist.