Ethyl acetate process

This Johnson Matthey DAVY™ process is a breakthrough in ethyl acetate (EA) production. We have developed a process that is ideally suited for use with bio-based ethanol feeds and so offers an EA production route that is almost 100% carbon neutral.

Our process is also compatible with petrochemical ethanol feeds where necessary.

Our novel technology has received a number of industry awards, including the Kirkpatrick Chemical Engineering Achievement Award, the Institution of Chemical Engineers Crystal Faraday Award and the Royal Academy of Engineering MacRobert Award.

Johnson Matthey has developed a process that enables ethyl acetate and a valuable hydrogen by-product stream to be produced directly from ethanol. The process takes advantage of the current industrial focus on renewable resources and the expansion in fermentation ethanol production and breaks the feedstock link to volatile oil prices.

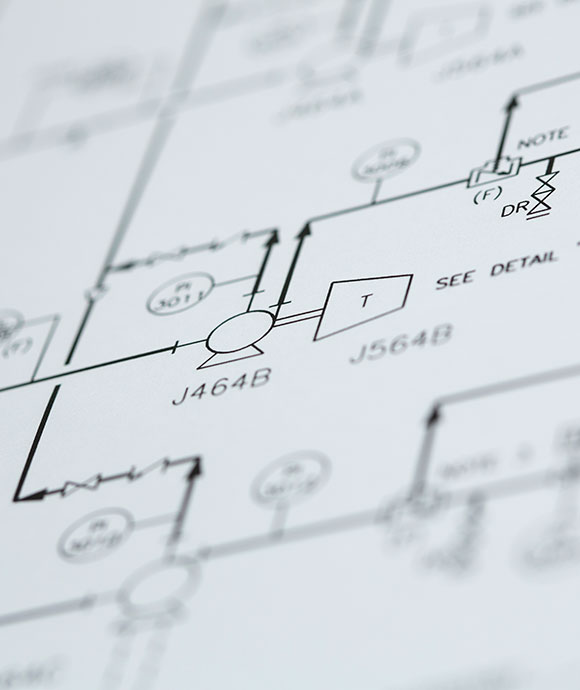

Dry ethanol is dehydrogenated to produce a crude ethyl acetate stream. This is selectively hydrogenated to remove certain by-products that cannot be separated by distillation. The innovative refining section then splits the azeotrope to produce a high purity ethyl acetate product. Unreacted ethanol is recycled to a dehydration unit where it is combined with fresh ethanol and dried.

Contact us for more information on the DAVY ethyl acetate process.