Our experts leverage many years of experience. Technical competency is the second highest feedback category after the product quality.

Optimise your plant operations

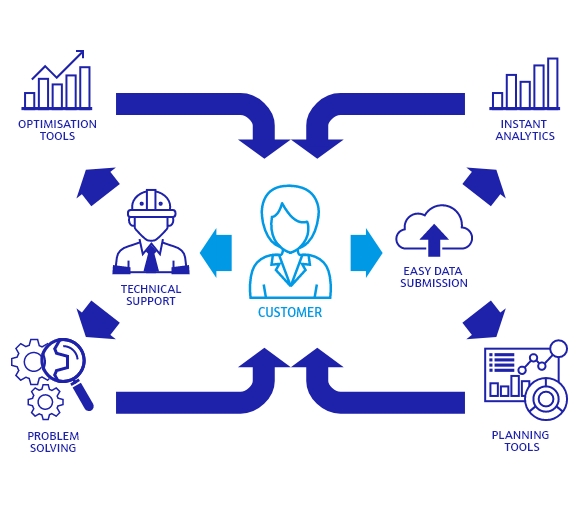

Complementing Johnson Matthey’s leading PURASPEC™ purification solutions, the JM-LEVO™ Purification portal is here to assemble, visualise and inform customers of their plants’ operations and opportunities.

The online portal provides a centralised interface for sharing and viewing data, visualising key metrics, monitoring the performance of the operation and communicating with JM. JM-LEVO Purification will provide value to plant operators by:

- Minimising data errors and driving time efficiencies through automated data submission

- Viewing the latest plant data instantly through dynamic dashboards

- Ensuring continuous plant operation by identifying when absorbent changes need to be made

- Utilising the JM technical service expertise to guide you to the best product solution for your duty based on actual operating data

- Communicating directly to JM technical service

Unified Data Platform: Access all vessel data across multiple sites in one centralized platform. Enhance data accessibility for stakeholders, ensuring seamless collaboration and decision-making.

Preventing plant disruptions: Detect deviations from normal conditions early, enabling swift troubleshooting to prevent equipment damage, plant disruptions and avoid costly visible damage.

Optimized Absorbent Management: Monitor inlet conditions and predict bed-life accurately. JM LEVO Purification helps you plan absorbent changeouts in advance, avoiding supply chain disruptions and eliminating costly airfreight for urgent shipments.

Preventative Maintenance: By closely monitoring absorbent beds, can optimize conditions to prevent fouling and equipment corrosion. This could lead to reduced maintenance costs and fewer shutdowns, maximizing operational efficiency and lead to better plant reliability.

Achieve maximum plant performance with JM

JM’s purification technical team has over 40 years of experience developing and supplying absorbent and catalyst solutions. We support our customers in achieving maximum performance in their operations while keeping CAPEX and OPEX down.

The purification technical team is represented by regionalised experts in the purification of natural gas, refineries streams and sustainable feedstocks. The team is available for all technical queries customers may have, from initial idea inception to performance monitoring and troubleshooting to changeout and spent materials recycling.

Our engineers are close to your site to provide support, reduce risk, save time and money.

Our subject matter experts can provide deep insight so you do not need to develop those capabilities in-house.

We will assist you in dealing with the waste product by completing the paperwork, liaising with third parties, ensuring local laws compliance, and obtaining the certificate of destruction.

Dynamic plant optimisation support

In a world moving at pace, JM understands the significance of responding and adapting quickly. JM-LEVO Purification allows us to support our customers dynamically.

Automatic data ingestion means that our Technical Service engineers work with up-to-date data to give the best possible troubleshooting and plant optimisation advice. The model behind the portal will also allow JM to predict changeout timing giving plenty of warning for the customers to budget and plan.

Benefits of JM-LEVO Purification

In a cost-focused world, JM-LEVO Purification can help you avoid unbudgeted expenses.

Performance

Stay agile and identify potential problems in operations quickly through review of the latest operating data

Optimise production and hit your objectives by maximising the performance of the loaded absorbent

Get absorbent improvement advice from actual plant data review

Simplicity

Get immediate insights and reports from uploaded data via the online dashboard.

Make planning easy through performance monitoring and comparisons across multiple sites and plants.

Save time with clear recommendation on absorbent reload timing.

Expertise

Use our historic knowledge and proprietary models to reduce operational risk and time-to-reload.

Share data and collaborate with world-class engineers.

Troubleshoot problems and find solutions quickly with expert support.

Contaminants analysis

At JM, we are always looking for ways to further enhance the experience of our customers. We are aware that analysing contaminants is not trivial and often not available onsite at the plant.

Our PURAVUE™ service is in development to address this and our chloride monitoring kit is launching as our first analytical solution. This analytical solution is complementary to the JM-LEVO Purification portal.

Download our chloride monitoring flyer