The growing demand for methanol to jet

The demand for scalable, cost-effective sustainable aviation fuel (SAF) has never been greater. SAF mandates, combined with ever-growing passenger numbers, are driving airlines to seek out new ways to secure their supply of sustainable aviation fuel. While various SAF production methods exist, it is still a new industry, causing manufacturers to face challenges such as feedstock limitations and high costs.

JM and Honeywell UOP are joining forces to offer a methanol to jet solution, designed to deliver additional SAF production worth over $200M over the life of a typical CO₂-to-methanol SAF plant1. This partnership provides access to jet fuel made from renewable sources, enabling global SAF mandates to be met.

Benefits of integrating CO₂-to-methanol and methanol-to-jet technologies

JM’s eMERALD™ CO2-to-methanol technology provides 98% carbon and hydrogen efficiency, resulting in maximum feedstock utilisation. It is backed up by JM’s 60 years of experience supplying leading methanol technology and catalysts to industry. Honeywell’s eFINING™methanol to jet technology provides high SAF yield and selectivity and maximises carbon utilisation.

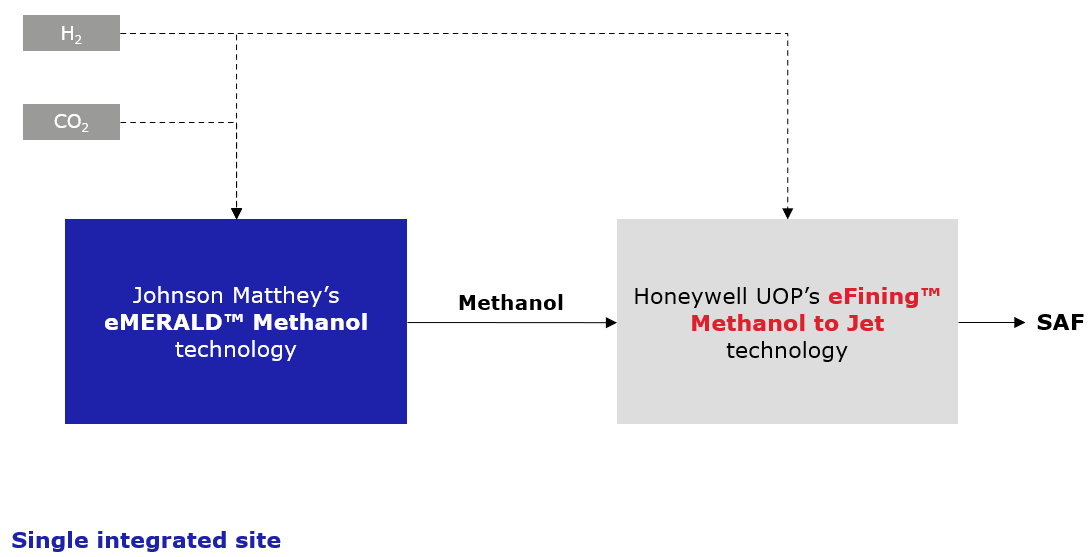

The integrated process provides customers with a pathway that converts H2 and CO2 to methanol, which is then converted into SAF. The unique combination of the technologies provides efficient hydrogen feedstock usage for SAF production, unlocking additional annual revenues and lowering costs.

Compared to both standalone methanol and methanol to jet units, our combined solution can deliver:

- Enhanced feedstock utilisation: More SAF produced per tonne of hydrogen feedstock used.

- Optimised cost: Reduced operating expenditure.

- Increased returns: Additional annual revenues of $8.3M for a typical plant.

SAF’s impact on the environment

According to the International Air Transport Association (IATA), SAF could contribute 60-70% of the aviation sector’s reduction of emissions needed to achieve net zero in the next 20-30 years. When used in aircrafts, SAF offers the ability to reduce net CO2 emissions by up to 80% without engine modification.2

JM's proven eMERALD CO2-to-methanol and Honeywell UOP’s eFining™ integrated technology enables a 30% saving in overall utility consumption in SAF production. The jet fuel produced is a drop-in fuel, fully compatible with existing infrastructure, helping the industry reach its sustainability targets.

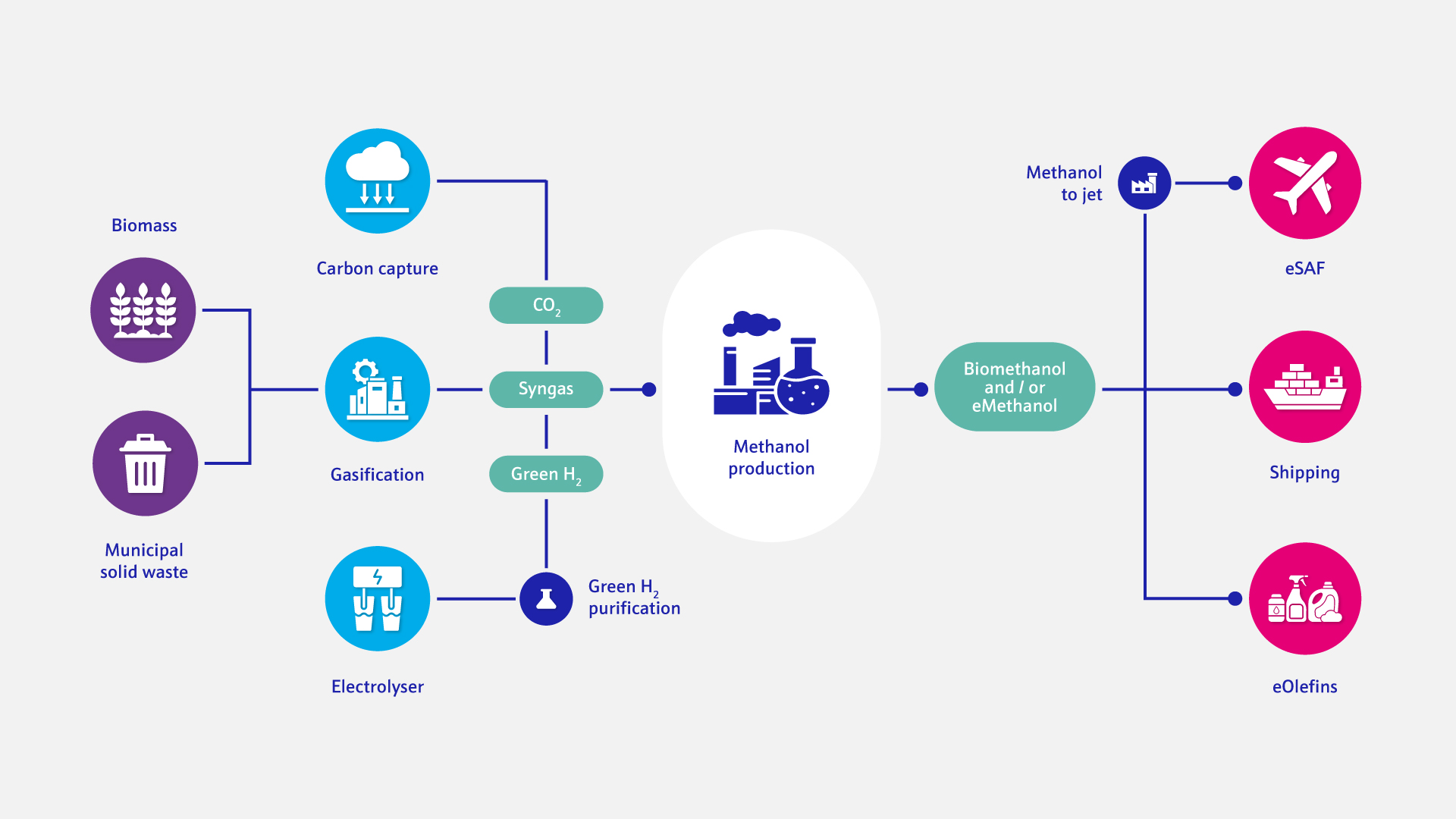

Methanol has the potential to enable decarbonisation across a wide range of industries. Methanol can be easily handled and is bio-degradable, facilitating adoption to decarbonise the chemicals industry and transportation. When used directly as a fuel, for example in the shipping industry, methanol offers significant reductions in harmful emissions compared to conventional fuels.

Get in touch

With a range of solutions available, our team will help you select the right technology for your journey.

Read more

News

Honeywell UOP and Johnson Matthey join forces to cut costs and boost deployment of sustainable fuels

Read nowNews

HIF Global initiates engineering for US sustainable aviation fuel facility, selects Johnson Matthey and Honeywell technologies

Read nowSolutions

eMERALD CO₂ to methanol technology: Our reliable and low-risk process has been optimised to achieve close to 100% hydrogen and carbon uptake to fully utilise these highly valuable feedstocks, whilst also minimising the overall energy requirements and operating costs.

Learn more1Based on 4,000 tpa SAF x 2071 USD/ton for a 133tpa H2 consumption.

2https://www.iata.org/en/programs/sustainability/sustainable-aviation-fuels