Selective catalytic reduction (SCR)

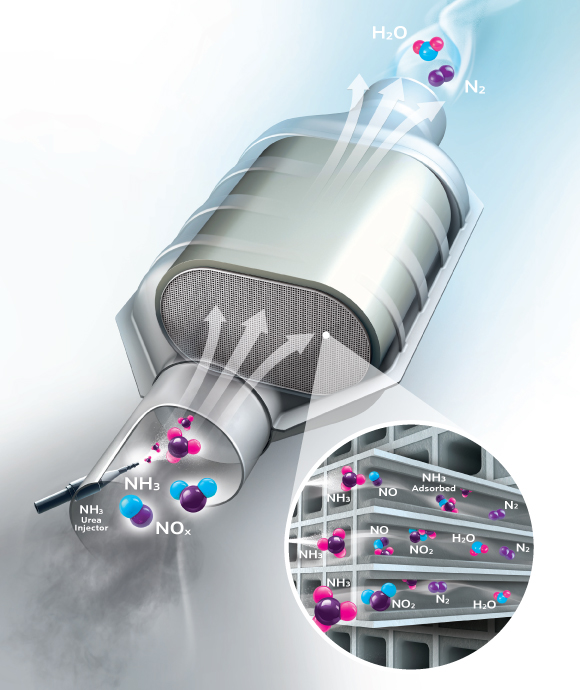

Selective catalytic reduction (SCR) systems work by chemically reducing NOx (NO and NO2) to nitrogen (N2). Johnson Matthey offers coated and extruded catalysts.

In a lean gas stream, it is necessary to add a reductant such as ammonia to the system to enable this reaction. Ammonia-SCR systems react ammonia (NH3) with the NOx to form nitrogen (N2) and water (H2O). There are three reaction pathways:

4NH3 + 4NO + O2 → 4N2 + 6H2O

2NH3 + NO + NO2 → 2N2 + 3H2O

8NH3 + 6NO2 → 7N2 + 12H2O

Any source of ammonia can be used, but most commonly the source is an aqueous solution of urea. This decomposes in the exhaust stream in two stages to form ammonia and carbon dioxide (CO2):

NH2C(O)NH2 → HNCO + NH3

↓

HNCO + H2O → CO2 + NH

Composition: Cu or Fe Zeolite or V-Titania coated on a flow-through monolith substrate.

Uniquely, we also offer extruded SCR catalysts which benefit from proven performance advantages as they have a catalytically active monolith.

Our selective catalytic reduction technology…

- Benefits from market-leading Cu-Zeolite technology and a range of high-performance V-Titania systems.

- Is developed for individual applications through our close work with the customer.

- Helps enable our customers to meet increasingly stringent legislation.

- Is highly durable against temperatures and poisons.

- Has excellent functionality across a large temperature window.

- Are being developed to help catalyst after-treatment systems achieve low N2O emissions, supporting future legislation requirements.