1974

JM produced the world's first autocatalyst

c. 112k

additional tonnes of NOx removed from tailpipes by JM catalytic converters in 2024/25

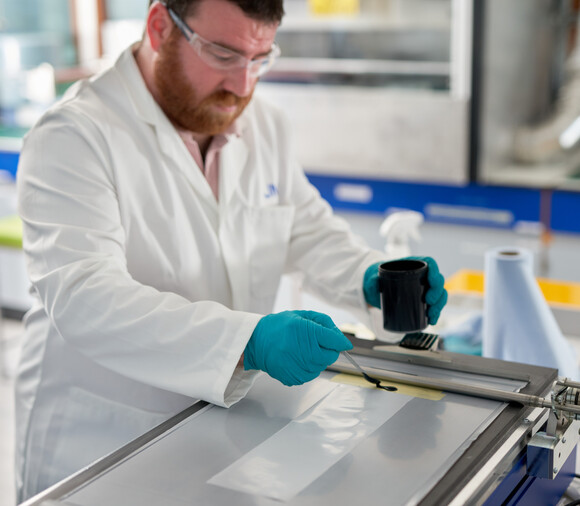

We're a world leader in the development and manufacture of catalysts for the automotive, energy and chemical industries. Our catalysts help remove pollutants, improve the efficiency of important industrial processes and unlock the potential of new sustainable fuels.

What is a catalyst?

Catalysts are used to speed up a chemical reaction. For a reaction to take place, chemical bonds must be broken and new ones formed. This requires energy. A catalyst lowers this activation energy barrier, so the molecules can react more easily. In fact, some chemistry is accelerated so much by catalysts, it wouldn’t take place at all without one.

Catalysts allow us to make chemical reactions happen at lower temperatures and pressures, saving energy and improving sustainability. They can also make a reaction very specific, minimising unwanted by-products that would otherwise need to be disposed of.

Since catalysts aren’t consumed by the reactions themselves, a small amount of catalyst goes a long way.

Expertise across different catalyst applications

At JM, we have expertise in different types of catalysts for lots of different applications across the automotive, energy and chemicals industries.

Much of our catalysis offering is heterogenous – involving solid catalysts that catalyse gaseous reactions. This includes our leading emission control catalysts which clean up harmful gaseous emissions, our high-performance hydrogen electrolyser catalysts which split water vapour into hydrogen and oxygen, and our pioneering catalysts for the production of sustainable fuels from gasified waste.

We also provide homogenous catalysts for the chemicals industry – predominantly liquid catalysts that are used in liquid reactions. For example, our platinum group metal catalysts are used to produce important chemicals from active pharmaceutical ingredients (APIs) through to high performance plastics, rubbers and adhesives.

While chemical catalysis is used throughout industry, we’re also taking inspiration from nature and developing complementary biocatalyst solutions, like enzymes. These are catalysts that come from living organisms, such as cells or bacteria. At JM, we use our expertise to identify, develop and manufacture biocatalysts for making pharmaceuticals and agrochemicals.

Customisable and cost-effective catalysis

This expertise means that we can better customise our catalysts to meet our customers’ needs, balancing trade-offs between catalytic activity, durability and cost. In our autocatalysts for example, we can alter the ratio of different metals as metal prices fluctuate, to reduce the cost of the product while ensuring the same performance.

And it’s not only the catalyst itself that has an impact. We also understand the surface chemistry interactions between the catalyst and support. For example, we coat our hydrogen fuel cell catalysts onto solid membranes and adjust both the catalyst and the membrane to optimise the performance.