1.6 million

tonnes per year licensed capacity

13

plants

25+ years

of operation

Technology for natural detergent alcohols production

Natural detergent alcohols (NDAs), or fatty alcohols, are high-molecular-weight, straight-chain primary alcohols essential to the production of detergents, surfactants, personal care products and cosmetics. They are produced from fatty acids formed by hydrolysis of natural fats and oils, such as palm kernel oil.

Johnson Matthey has licensed the greatest natural fatty alcohol production capacity worldwide. You can be confident that our technology will maximise the cost-efficiency of your process, giving you longer catalyst life, high yield, and improved safety.

Make natural detergent alcohols efficiently, reliably and profitably with Johnson Matthey's technology

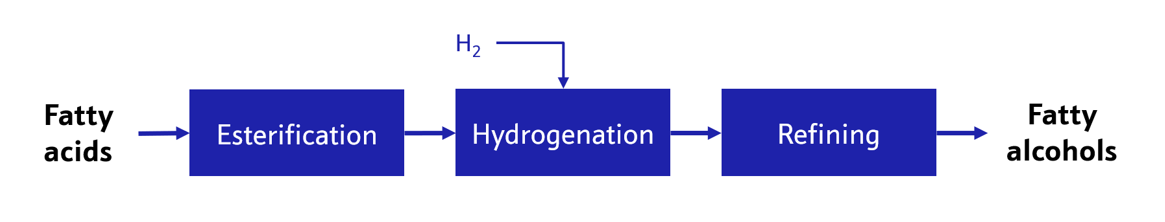

Esterification of fatty acids to methyl esters

JM’s natural detergent alcohol production process begins with the esterification of natural fatty acids into methyl esters.Our esterification technology minimises your feedstock use as it achieves almost complete conversion of the acids into esters. It uses a highly selective, and easy to manage heterogeneous catalyst in a reactive distillation system. The reaction column includes a smart system that allows on-line replacement of the catalyst with no loss of production, increasing uptime.

In addition, the esterification step creates a non-acidic downstream environment, enabling the use of low-cost carbon steel and saving on CAPEX.

Hydrogenation of methyl esters

The methyl esters are then hydrogenated in the vapour phase using a heterogeneous, low-cost, base metal catalyst. JM’s natural detergent alcohols production technology leverages our vapour-phase hydrogenation loop, which creates less by-product and is inherently safer to operate than liquid-phase hydrogenation loops. It enables low pressure operation, eliminates hot-spots and it can be easily and quickly put in a safe condition. Its features also result in increased catalyst lifespan and performance, meaning that the catalyst delivers high conversion for many years before it needs to be replaced.

Producing natural detergent alcohols efficiently, safely, and over the long-term

Our natural detergent alcohol production process delivers:

- >98% product yield.

- Milder, safer operating conditions at low pressure

- A low-cost, high-performance base metal hydrogenation catalyst with extended lifespan.

- Use of heterogeneous catalysts, which are easy to manage.

- A smart esterification catalyst system which allows on-line replacement with no loss of production.

- No generation of acidic waste liquid streams.

- A well-proven design, used at 13 operating natural detergent alcohols plants.