60,000

tonnes per year licensed capacity

2

plants in operation

30 years

experience in esterification and hydrogenation

1,6-Hexanediol is used across a wide range of end-industries, including coatings, adhesives, and resins. Thanks to its chemical structure, it is commonly applied in polyurethane and polyester production, providing enhanced mechanical and physical properties to its final products.

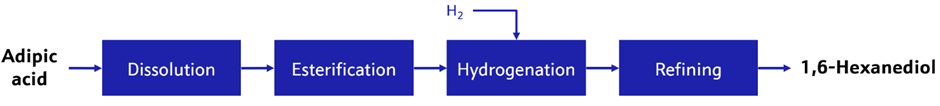

Johnson Matthey’s 1,6-Hexanediol production technology uses our extensive esterification and hydrogenation expertise. It combines our reactive distillation esterification system with a vapour-phase hydrogenation loop and use of solid catalysts to deliver:

- Maximised feedstock conversion

- Improved safety during operation

- Simpler operation and high uptime

Leveraging our industry-leading capabilities, we can enable your continuous production of 1,6-Hexanediol from adipic acid.

Make 1,6-Hexanediol using efficient, safe, and proven technology from Johnson Matthey

Dissolution and esterification of Adipic Acid

During JM’s 1,6-Hexanediol production process, adipic acid (also known as hexanedioic acid) undergoes esterification and is dissolved and then undergoes esterification into dimethyl adipate. Our esterification technology minimises your feedstock use and achieves almost complete conversion of the adipic acid into dimethyl adipate. It achieves this by using our reactive distillation system and highly selective, heterogeneous catalyst which is easy to manage. The reaction column also includes a smart system that allows on-line replacement of the solid catalyst with no loss of production to increase uptime. In addition, the esterification of adipic acid creates a non-acidic downstream environment, enabling the use of low-cost carbon steel and saving on CAPEX.

Hydrogenation of Dimethyl Adipate

Following esterification in 1,6-Hexanediol production, hydrogenation is carried out in the vapour phase using a heterogeneous, low-cost, base metal catalyst. JM’s 1,6-Hexanediol production technology leverages our vapour-phase hydrogenation loop, which creates less by-product and is inherently safer to operate than liquid-phase hydrogenation loops.

It enables low pressure operation, eliminates hot spots and can easily and quickly be put in a safe condition. These features also result in an extended catalyst life, meaning that the catalyst delivers high conversion for many years before it needs to be replaced, thereby extending increasing uptime.

Refining 1,6-Hexanediol

Finally, the crude 1,6-Hexanediol is refined to the high purity required for polymer production, using an advanced distillation system with high energy efficiency.

Profitable production of high purity 1,6-Hexanediol

Our esterification and vapour-phase hydrogenation technologies have been widely deployed at multiple Butanediol, Natural Detergent Alcohols and LP Oxo℠ plants around the world.

- Achieves higher feedstock efficiency and reduced by-product output under mild operating conditions, offering your oxo alcohol plant low operating costs and enhanced safety.

- Provides you with a wide range of options to tailor the process to production goals.

- Achieves a high-quality oxo alcohol output for both polymer and chemical-grade propylene feedstocks.

- Uses a simple hydroformylation catalyst management system that drives high uptimes.

- Reduces capital expenditure and plot requirements due to less and smaller equipment.