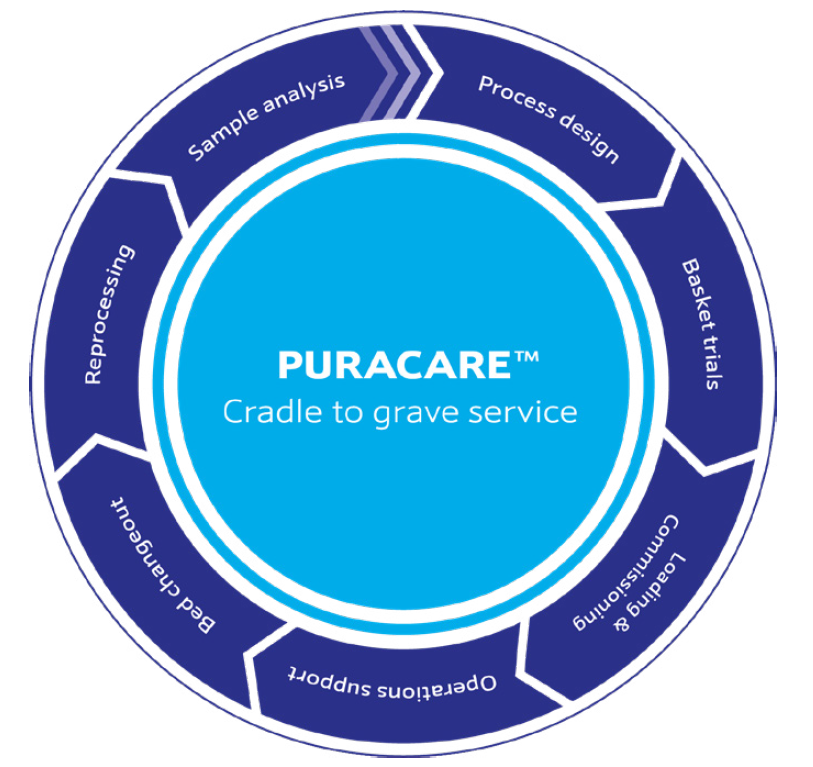

PURACARE service

Guaranteed peace of mind

PURACARE™ tailored service is designed to take care of all aspects of operation, maintenance and absorbent/catalyst recycling for our global customers in the Gas Processing industry. Under the expert direction of the Johnson Matthey team, this hands-on service enables customers to save time and manpower, and also to comply with all current and anticipated environmental legislation.

Design considerations

Johnson Matthey’s experienced engineers will provide an optimum absorbent/catalyst and reactor vessel design tailored to the customer’s conditions and targets. This includes a specialist consultancy on change-out requirements such as access to vessel and sufficient laydown for media and change out equipment

Delivery and loading

Johnson Matthey will manage the delivery of the agreed products to the customer plant and load these using the most appropriate technique for the type of reactor vessel and site conditions. Experienced on-site consultants can be at hand to provide advice and assistance during the loading.

Optimum operation

Expert advice is offered to make the most cost-effective use of PURASPEC products in your plant. Johnson Matthey’s experienced and dedicated team will monitor and support the operation to maximise bed life. Towards the end of life, recommendations on the timing for absorbent replacement will be provided.

Material discharge

Prior to discharge, Johnson Matthey can provide consultation on the safe and best discharge operation for the particular unit. Johnson Matthey can provide trained people and suitable equipment to facilitate the clean and safe discharge of the used absorbents and catalysts.