NOx control systems

JM's SCR systems are designed to reduce >95% of NOx emissions for stationary diesel and gas engines. Our products are reliable, resilient, and meet air quality standards around the world.

Our SCR systems can be coupled with ammonia slip or oxidation catalyst technology for optimal reductions of CO, hydrocarbons, ammonia and other VOCs.

JM's SCR technology has achieved an impressive 15,000-plus hours of operation before maintenance is required.

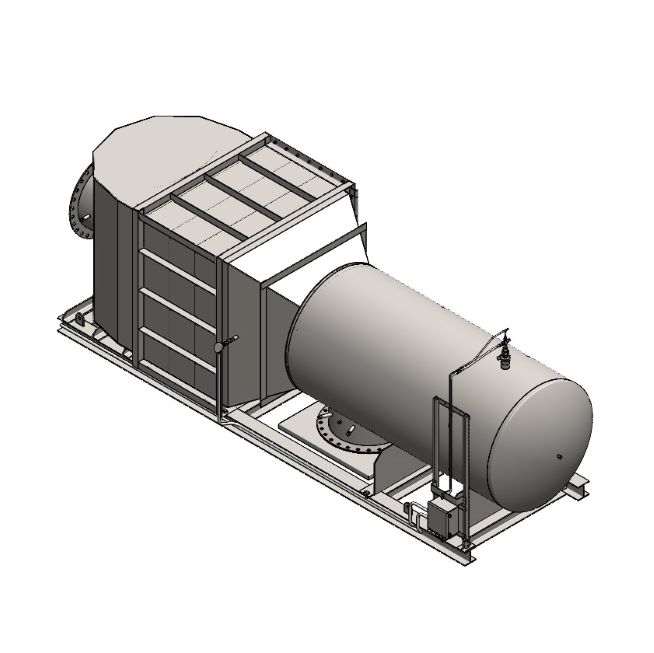

JM’s SCR systems include the following options as key components:

- SINOx honeycomb catalysts

- Durable stainless steel catalyst housings

- Stainless steel reagent injection lance

- Stainless steel reagent mixing duct

- System control panel and reagent dosing pump

- Silencers for additional sound attenuation

Download emission control solutions brochure